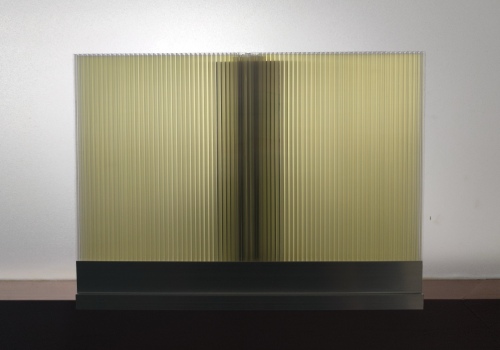

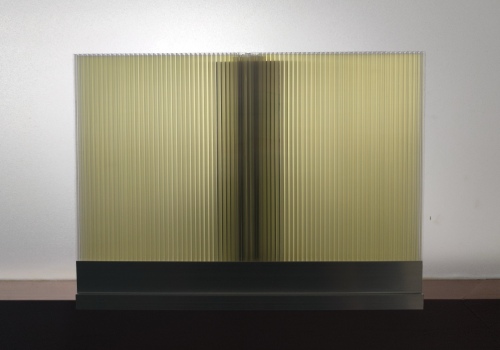

Polycarbonate Ceiling Panels are translucent ceiling systems that are functional, stylish, and makes a statement by elegantly diffusing room lighting.

This easy access enables swift maintenance while creating a unique look in your design. Available in a variety of finishes and translucencies and fully customizable, the Facaplex is an ideal choice when you want to add a soft touch to your interior lighting.

Benefits of Using Polycarbonate Panels for Ceilings

Easy Installation

Polycarbonate panels are designed to fit into traditional suspended ceiling systems. This simplifies installation for contractors and reduces construction time compared to custom ceiling solutions.

Light Diffusion Without Glare

The panels evenly diffuse incoming light, creating a soft, natural illumination that eliminates harsh shadows or glare, making interiors more comfortable and visually appealing.

Compatibility with Various Thicknesses

Polycarbonate panels can accommodate a range of thicknesses, typically from 8mm to 50mm. This allows for flexibility in design, insulation, and structural needs, making them adaptable to different ceiling projects.

Lightweight Design

Polycarbonate panels are much lighter than glass or traditional ceiling materials. This reduces the structural load on your building, making installation faster, safer, and less labor-intensive. Lighter ceilings also minimize stress on supporting beams and frames.

High Impact Resistance

Polycarbonate is extremely strong and resistant to breakage. Unlike glass, it can withstand accidental impacts without shattering, making it ideal for areas prone to physical contact or harsh conditions.

Excellent Light Transmission

Polycarbonate panels allow natural light to pass through while diffusing it evenly. This brightens indoor spaces, reduces the need for artificial lighting, and helps save on energy costs without compromising privacy.

Durability and Longevity

Thanks to their strong material properties, polycarbonate ceilings last longer than traditional materials. They maintain their appearance and structural integrity over time with minimal maintenance.

Easy Maintenance

Polycarbonate panels are easy to clean with just water and mild detergents. They do not require regular painting or sealing, reducing upkeep costs and effort.

Design Flexibility

These panels can be cut, bent, and shaped to fit different ceiling designs. They support creative architectural ideas, including skylights, curved ceilings, and decorative patterns.

Energy Efficiency

By allowing natural light in and blocking heat, polycarbonate panels help regulate indoor temperature. This reduces the reliance on heating, cooling, and lighting systems, lowering overall energy consumption.

Specifications of Polycarbonate Panels

| Material | Polycarbonate Panels |

|---|---|

| Thickness | polycarbonate solid sheet: 1mm - 50mm |

| Fire Resistance | UL94 V0, V2 |

| Temperature Adaptability | Long-term operating temperature: -40°C to +120°C. |

| Light Transmission | With varying colors, the light transmittance can reach up to 90%. |

| Impact Resistant | The impact strength is 250 times of glass and 30 times that of acrylic. |

| Weather Resistant | Co-extruded UV-resistant coating, ensuring excellent outdoor weather resistance. |

Polycarbonate Ceiling Design Ideas for Different Spaces

Schools

Translucent polycarbonate panels in geometric patterns can define classrooms and hallways, while colorful accents inspire creativity. Backlit strips add a modern, tech-friendly touch. Trend-wise, modular panels that can be reconfigured for different classroom layouts are gaining popularity, combining flexibility with durability.Office Buildings

Linear or grid-pattern polycarbonate ceilings give offices a clean, organized look. Frosted panels with integrated LED lighting produce a soft, professional ambiance, and layered designs highlight meeting rooms or communal areas. Current design trends favor mixed textures and subtle translucency to create dynamic, visually appealing workspaces.Libraries

Vaulted or wave-shaped polycarbonate ceilings add elegance and visual interest. Translucent panels with subtle patterns diffuse light evenly, reducing glare and creating calm, inviting spaces. Designers are increasingly using layered panels to frame reading nooks or highlight architectural features.Recreational Facilities

Gyms and sports halls can use corrugated or modular polycarbonate ceilings in bright colors or team-themed patterns. Backlit sections enhance energy and motion, while impact-resistant panels ensure durability. Trend ideas include integrating transparent panels with ceiling graphics to energize the space.Government Buildings

Layered or coffered polycarbonate ceilings bring modern character to auditoriums and lobbies. Frosted or tinted panels with clean lines convey professionalism, and the material’s low maintenance suits high-traffic public areas. Designers are experimenting with patterned translucency to subtly reinforce institutional branding.Commercial Buildings

Colored, patterned, or semi-transparent polycarbonate panels define zones in showrooms and malls. Curved or segmented designs guide foot traffic and create flow, while the sleek panels enhance aesthetics and support branding. Current trends favor mixed-panel shapes and lighting integration to make spaces memorable.Healthcare Facilities

Smooth, flowing polycarbonate ceilings with soft translucency improve lighting in hospitals and clinics. Subtle backlighting creates calming pathways, and hygienic, easy-to-clean panels support a healing environment. Designers now often combine soft curves and gentle color gradients to reduce stress and create a welcoming atmosphere.

Services Offered By Facaplex

Facaplex provides fabrication and thermoforming services for polycarbonate solid sheets, complemented by top-tier silkscreen printing. Our skilled team can create tailored shapes and designs, improving both the aesthetic and functional aspects of polycarbonate products for a wide range of applications.

1. Vacuum thermoforming for polycarbonate sheets

DBI showcase the iconic columns on the main entry of W Brisbane, with a reflective ceiling and illumination to create a unique effect.

But polycarbonate materials convey the concept of a lightweight and light-transmitting design concept, they also retain the metallic texture of aluminum panels.

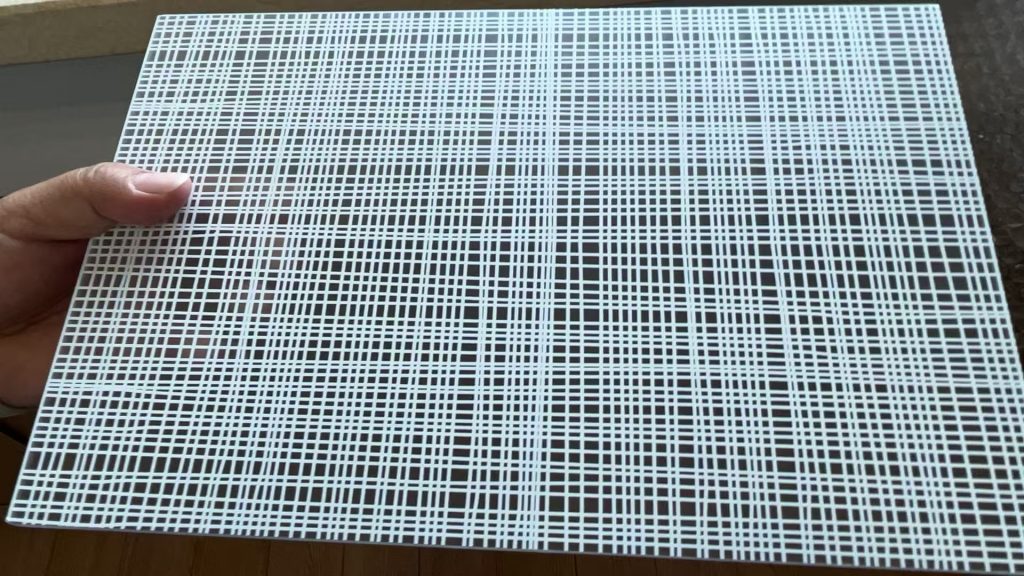

2. Silkscreen printing and digital printing on polycarbonate sheets

Allows for personalized graphics, logos, and text tailored to specific preferences. Offers efficient printing for both small and large projects.

Louis Vuitton Maison Osaka Midosuji utilizes washi paper and glass curtain walls in its design. However, polycarbonate (PC) can achieve a similar effect when silk screen printing techniques, providing a lightweight and versatile alternative that captures the aesthetic qualities of traditional materials.

Why Choose Facaplex For Polycarbonate Ceiling Panels

- Expertise in Manufacturing

As a leading polycarbonate manufacturing and fabrication factory, we specialize in products and processing manufacture.

We’re a group company specialized in construction field, we can produce a wide range of aluminum products tailored to your specific plastic sheets need. - Design Capability

Our team of experienced professionals is committed to transforming your ideas into innovative solutions. We work closely with clients to deliver customized designs that align with their vision and functional requirements. - Quality Assurance

We prioritize quality at every stage of production, from sourcing raw materials to final inspection, ensuring that our products exceed industry standards. - Competitive Pricing

Our efficient manufacturing processes and direct sourcing of materials enable us to offer competitive pricing without compromising on quality. - Short Delivery Time

- Comprehensive Support

From initial consultation to modular facade design, post-production transportation support, we provide comprehensive assistance throughout the entire project.

FAQ

What are polycarbonate ceiling panels

Polycarbonate ceiling panels are durable, lightweight sheets made from a tough thermoplastic polymer. Their main advantages over traditional materials like glass include superior impact resistance (virtually unbreakable), excellent light transmission, UV protection, significant thermal insulation properties, and a much lighter weight, making them safer and easier to install.

how long do polycarbonate ceiling panels typically last?

Polycarbonate ceiling panels are exceptionally durable, known for their high impact resistance and ability to withstand extreme weather conditions, including hail, snow, and strong winds. With proper installation and maintenance, high-quality panels typically come with warranties ranging from 10 to 20 years, but can often last much longer in good condition.

Are polycarbonate ceiling panels UV resistant and will they yellow over time?

Yes, most high-quality polycarbonate ceiling panels are co-extruded with a protective UV-resistant layer on one or both sides. This layer is crucial for preventing the panels from yellowing, becoming brittle, or losing their clarity due to sun exposure, ensuring they maintain their aesthetic and performance over their lifespan.

Can polycarbonate ceiling panels provide good thermal insulation?

Absolutely. Multi-wall polycarbonate ceiling panels, which feature internal air pockets, are particularly effective at providing excellent thermal insulation. These structures trap air, significantly reducing heat transfer and making them ideal for conservatories, greenhouses, and skylights where temperature control and energy efficiency are important.

Are polycarbonate ceiling panels difficult to install

No, polycarbonate ceiling panels are generally easier to install than glass due to their lightweight nature and flexibility. They require a stable support structure, typically made of aluminum, steel, or wood, with appropriate purlin spacing to prevent sagging. Installation usually involves specific H-profile connectors and U-profile end caps, along with sealing tapes and screws, to ensure a watertight and secure fit.

How do I clean and maintain my polycarbonate ceiling panels?

Cleaning polycarbonate ceiling panels is straightforward. Use lukewarm water with a mild, non-abrasive soap or detergent and a soft cloth or sponge. Avoid harsh chemicals, abrasive cleaners, or stiff brushes, as these can scratch the surface or damage the UV protective layer. Rinse thoroughly with clean water to remove any soap residue. Regular cleaning helps maintain clarity and appearance.

Are there different types or colors of polycarbonate ceiling panels available?

Yes, polycarbonate ceiling panels come in a wide variety of types and colors to suit different needs and aesthetics. Options include clear (maximum light), opal/translucent (diffused light, reduced glare), bronze/grey (heat reduction, tinted appearance), and even specific colors. They are also available as solid sheets, twin-wall, multi-wall (e.g., triple-wall, five-wall), and corrugated profiles, each offering different levels of insulation and strength.

Can polycarbonate ceiling panels be easily cut to size

Yes, polycarbonate ceiling panels are highly versatile and can be easily cut to size to fit specific project dimensions. Standard power tools such as circular saws, jigsaws, or even utility knives (for thinner sheets) with fine-tooth blades are suitable for cutting. This ease of fabrication allows for custom installations in various architectural designs

Get Free Quote of Polycarbonate Curtain Wall

Looking for durable ceiling panels for your project? Facaplex offers polycarbonate panels built for offices, shopping centers, warehouses, and industrial sites. Available in standard or custom sizes to fit your specific requirements, they provide long-lasting performance, UV protection, and impact resistance. Request a free quote today for bulk orders and enjoy reliable delivery and consistent quality with Facaplex.

Related Products

Related News

Twinwall polycarbonate roofs are a versatile and durable solution for both residential and commercial projects. Known for their lightweight yet […]

Multi-Wall Polycarbonate is a versatile building material known for its unique combination of strength, light weight, and thermal efficiency. Unlike […]

Choosing the right roofing material can make a huge difference in both the durability and appearance of your outdoor or […]

Understanding Twinwall Polycarbonate Roof Features Polycarbonate pergola roof stands out for its lightweight yet strong structure. This material resists impacts […]

The main difference between twin wall polycarbonate and multiwall polycarbonate lies in the number of layers. Twin-wall polycarbonate features two […]

The difference between solid and multiwall polycarbonate sheets lies in their structure and performance. Solid polycarbonate looks like glass and […]

Selecting the right thickness for polycarbonate panels greatly impacts performance and longevity. People often compare polycarbonate versus glass, but polycarbonate […]

When choosing custom polycarbonate panels, buyers often look beyond basic durability. Key factors such as available sizes, cut-to-size options, thickness […]