Polycarbonate roofing sheets serve as a modern solution for both residential and commercial structures. These sheets offer outstanding strength, high light transmission, and impressive weather resistance. Facaplex polycarbonate roofing stands out by providing up to 90% visible light transmission, exceptional impact resistance, and built-in UV protection. The global polycarbonate roofing market reached about USD 4.71 billion in 2023, with roofing as the leading application segment.

| Metric | Value/Description |

|---|---|

| Market Size (2023) | Approximately USD 4.71 billion |

| Forecast CAGR (2024-2032) | Between 5.1% and 5.7% |

| Leading Application Segment | Roofing, driven by construction sector demand |

| Key Growth Drivers | Construction activities, material properties (strength, UV protection, fire resistance, aesthetics) |

*Facaplex polycarbonate sheets deliver durability and energy efficiency, making them the preferred choice for modern roofing needs.

What Is Polycarbonate Roofing?

Polycarbonate roofing is a lightweight, durable roofing material made from polycarbonate plastic sheets. It is widely used in both residential and commercial buildings for its high impact resistance, UV protection, and light transmission. Unlike traditional materials such as glass or metal, polycarbonate sheets combine strength and transparency, making them ideal for areas that need natural light without compromising protection.

Types of Polycarbonate Roofing Sheets

- Solid Polycarbonate Sheets: Clear and glass-like, used for skylights and canopies.

- Multiwall Polycarbonate Sheets: Hollow structure for improved insulation and strength.

- Corrugated Polycarbonate Sheets: Ideal for industrial roofs, offering drainage and flexibility.

Benefits of polycarbonate roofing

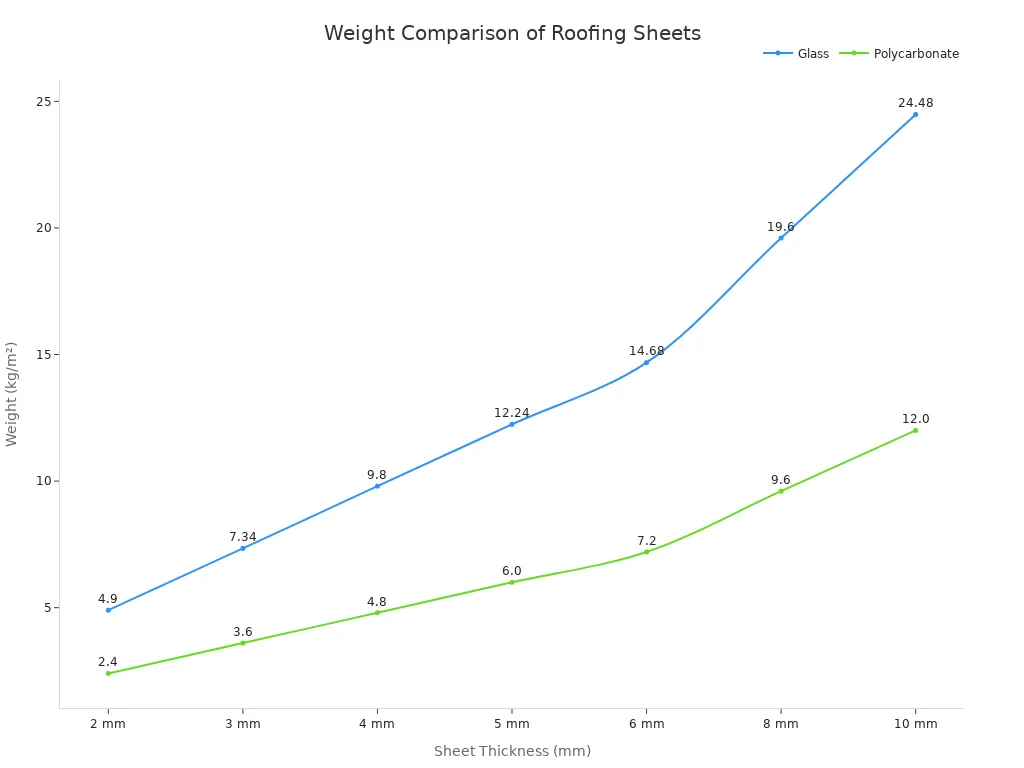

Lightweight and strong

Facaplex polycarbonate sheets offer a unique combination of lightness and strength. These sheets weigh about half as much as glass, making them much easier to handle and install. This feature reduces labor costs and speeds up construction. Polycarbonate roofing panels also provide excellent strength, with impact resistance up to 250 times greater than glass. This makes them ideal for areas where safety and durability matter.

- Polycarbonate sheets are available in various thicknesses, from 0.5 mm to over 20 mm.

- Thicker sheets are used for heavy-duty applications, such as industrial shields or bullet-resistant panels.

- Polycarbonate roof panels are a cost-effective roofing material, especially when compared to glass.

| Sheet Thickness (mm) | Glass Weight (kg/m²) | Polycarbonate Weight (kg/m²) |

|---|---|---|

| 2 | 4.90 | 2.40 |

| 3 | 7.34 | 3.60 |

| 4 | 9.80 | 4.80 |

| 5 | 12.24 | 6.00 |

| 6 | 14.68 | 7.20 |

| 8 | 19.60 | 9.60 |

| 10 | 24.48 | 12.00 |

*Tip: Polycarbonate roofing panels are not only lightweight roofing materials but also provide outstanding impact resistance, making them suitable for both residential and commercial projects.

UV protection

Facaplex polycarbonate sheets come with built-in UV protection. This feature blocks harmful ultraviolet rays, which can cause fading, yellowing, and brittleness in roofing materials. Scientific studies show that UV exposure breaks down chemical bonds in polycarbonate, leading to discoloration and loss of strength. However, UV-coated polycarbonate roofing panels maintain their clarity and structural integrity for decades.

- UV coatings prevent yellowing, cracking, and heat distortion.

- Polycarbonate roof panels with UV protection retain their original properties for many years.

- Manufacturers often back these products with long-term warranties.

*Note: Facaplex polycarbonate roofing panels absorb UV radiation, protecting both the material and the people or plants beneath the roof.

Weather resistance

Polycarbonate roofing stands out for its ability to withstand extreme weather. Facaplex polycarbonate sheets resist hail, heavy winds, and snow loads as well as, or better than, metal roofing. These panels do not dent or crack easily, even when exposed to hailstones or falling debris.

| Feature | Description |

|---|---|

| Wind and Snow Load | Withstands pressures up to 2,200 N/m² (wind speeds up to 125 mph) |

| Impact Resistance | Up to 250 times stronger than glass |

| Thermal Insulation | Multiwall design provides excellent insulation |

| UV Protection | Proprietary UV treatment on both sides |

| Weathering Tests | Passed 4,000-hour accelerated weathering tests |

| Warranty | 15-year limited warranty against discoloration and loss of strength |

| Fire Ratings | Meets CC1 (ASTM D635) and Class A (ASTM E-84) standards |

| Application Examples | Used in stadium roofing for durability in harsh climates |

- Facaplex polycarbonate roof panels resist temperatures from -40℃ to 120℃.

- These sheets are waterproof and provide excellent thermal insulation.

- Polycarbonate roofing panels are flame-resistant and self-extinguishing.

Durability

Facaplex polycarbonate sheets deliver long-lasting performance. Under normal usage, these sheets last 10 to 25 years, with some installations reaching up to 25 years or more. Proper installation and regular cleaning help extend their lifespan. Polycarbonate roof panels are less prone to corrosion and denting than metal roofs and do not shatter like glass.

- Polycarbonate roofing requires only simple maintenance, such as cleaning with mild soap and a soft cloth.

- Regular inspections help maintain the roof’s appearance and function.

- Facaplex polycarbonate roofing panels provide strong protection against UV rays, hail, wind, and heavy rain.

*Callout: Polycarbonate roofing panels are easier to install and maintain than metal or glass roofs. Their durability and low maintenance make them a smart choice for anyone seeking a reliable roofing solution.

Applications of polycarbonate roofing sheets

Greenhouses and Agriculture

Polycarbonate sheets play a vital role in modern agriculture. Farmers and growers use these sheets for greenhouse roofs and walls because they allow natural light to enter while providing strong insulation. Facaplex polycarbonate roofing sheets help maintain the right temperature for crops, which supports healthy growth and higher yields.

- Polycarbonate sheets with thicknesses between 1 and 1.5 mm balance light transmission and protection. They are lightweight and easy to install.

- Multi-wall polycarbonate panels offer excellent thermal insulation. They reduce heat loss by up to 60% compared to single-pane glass.

- These sheets provide uniform light diffusion. This helps plants grow evenly and protects them from sunburn.

- Facaplex polycarbonate sheets are highly impact-resistant. They protect crops from hail, wind, and other harsh weather.

- Farmers also use these sheets for animal shelters, canopies, and partitions. The material’s flexibility and UV protection make it ideal for many agricultural structures.

Growers have reported that switching to polycarbonate roofing sheets in commercial greenhouses leads to up to 25% annual energy savings. The panels’ durability and UV resistance also reduce maintenance costs and extend the lifespan of the structure.

*Tip: Facaplex polycarbonate sheets help extend the growing season and improve crop productivity by creating a stable, light-filled environment.

Sunrooms and Patios

Homeowners and builders often choose polycarbonate sheets for sunrooms and patios. These spaces benefit from the material’s ability to let in natural light while blocking harmful UV rays.

- Insulated polycarbonate patio covers help keep indoor temperatures comfortable all year. They reduce heat transfer and can lower energy bills.

- The foam core in some panels dampens noise from rain or wind, making outdoor spaces more pleasant.

- Facaplex polycarbonate sheets come in different levels of translucency and colors. This allows for privacy and control over the amount of light.

- The lightweight nature of the sheets makes installation simple. Homeowners can add fans, lighting, or hanging plants to their patios or sunrooms with ease.

Compared to traditional materials like glass, polycarbonate roofing sheets are more durable and require less maintenance. They withstand strong winds, heavy rain, and hail, making them a reliable choice for outdoor living spaces.

Walkways and shelters

Public spaces such as walkways, bus shelters, and stadiums require roofing that is both safe and durable. Facaplex polycarbonate sheets meet these needs with their unique properties.

| Benefit | Explanation |

|---|---|

| High Impact Resistance | Nearly unbreakable, providing superior safety against breakage. |

| UV Protection | UV protective layers extend material lifespan and protect interiors from sun damage. |

| Weather Resistance | Suitable for extreme climates, ensuring durability in tropical and cold zones. |

| Lightweight | Easy to handle and install, reducing labor and structural load. |

| Fire Resistance | Enhances safety by resisting fire spread. |

| Transparency | Allows natural light transmission while maintaining protection, improving visibility and safety. |

- Facaplex polycarbonate sheets are used in covered walkways, canopies, and transit shelters. Their high impact strength and weather resistance make them ideal for high-traffic areas.

- Textured polycarbonate sheets help illuminate paths with natural light and are durable enough for outdoor environments.

- The material’s UV protection and anti-scratch properties ensure long-lasting performance, even in busy public spaces.

*Note: Polycarbonate roofing sheets provide both safety and comfort in public walkways and shelters, making them a preferred choice for architects and city planners.

Commercial and residential buildings

Facaplex polycarbonate sheets are popular in both commercial and residential building applications. Their versatility and performance make them suitable for a wide range of uses.

- In homes, polycarbonate sheets are used for patios, verandas, greenhouses, and sunrooms. They provide natural light while protecting against UV rays and harsh weather.

- Interior designers use these sheets for room dividers and wall cladding. The material allows privacy without blocking light.

- Polycarbonate sheets are easy to cut and shape, making them user-friendly for DIY projects.

- In commercial and industrial buildings, polycarbonate sheets serve as roofing and wall panels. They allow daylight to enter large spaces, reducing the need for artificial lighting.

- Additional uses include skylights, windows, partitions, and facades. The material’s durability, light diffusion, and aesthetic appeal make it a favorite among architects.

| Aspect | Energy Efficiency Contribution |

|---|---|

| Natural Light Penetration | Reduces reliance on artificial lighting, lowering daytime energy consumption. |

| Insulating Properties | Helps maintain indoor temperatures, reducing heating and cooling costs. |

| Technological Advancements | Enhanced UV protection, scratch resistance, and thermal insulation improve overall energy performance. |

Facaplex polycarbonate roofing sheets help lower energy costs by providing excellent insulation and allowing up to 90% natural light transmission. Their durability and recyclability also support sustainable building practices.

*Callout: Builders and homeowners choose Facaplex polycarbonate sheets for their strength, energy efficiency, and design flexibility in modern building applications.

Polycarbonate roofing panels vs. other materials

Polycarbonate vs. glass

Facaplex polycarbonate roofing panels offer several advantages over traditional glass. Polycarbonate sheets weigh much less than glass, making them easier to transport and install. This lightweight quality reduces labor costs and allows for faster project completion. Polycarbonate roof panels also provide better impact resistance. While glass can shatter under force, polycarbonate sheets withstand impacts up to 250 times greater than glass, making them safer for homes and commercial spaces.

Insulation is another key difference. Polycarbonate roofing panels have a higher R-value than glass of the same thickness, which means they insulate better and help maintain indoor temperatures. The table below shows the difference in insulation values:

| Material | Thickness (mm) | R-value |

|---|---|---|

| Cellular Polycarbonate Glazing (CPG) | 25 | 3.84 |

| Double-pane Insulated Glass Unit (IGU) | 25 | 2.08 |

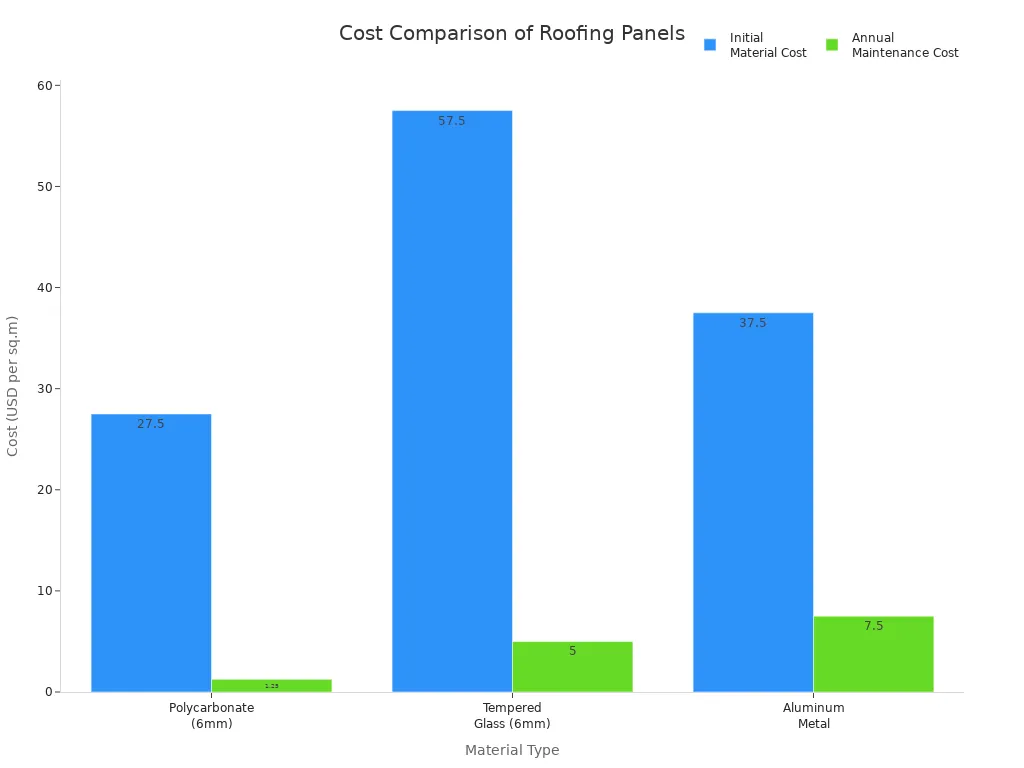

Cost also plays a major role. Glass roofing panels are more expensive and require specialized installation. Polycarbonate sheets, on the other hand, are more affordable and easier to handle. This makes Facaplex polycarbonate roof panels a cost-effective choice for many projects.

Polycarbonate vs. metal

When compared to metal roofing, Facaplex polycarbonate roof panels stand out in several ways. Polycarbonate sheets provide better thermal insulation than metal, helping to keep buildings cooler in summer and warmer in winter. Metal roofs often transfer heat quickly, which can lead to higher energy bills.

Impact resistance also differs. Metal roofing panels receive high ratings for withstanding hail and debris, but polycarbonate roof panels offer superior flexibility and strength. They resist cracking and denting, even under severe weather.

Cost and maintenance are important factors. Polycarbonate roofing panels have lower installation costs because of their light weight and easy handling. Maintenance is simple, usually requiring only occasional cleaning. The table below compares costs and maintenance:

| Material Type | Initial Material Cost (per sq.m) | Installation Cost Impact | Annual Maintenance Cost (per sq.m) | Notes on Long-Term Savings and Durability |

|---|---|---|---|---|

| Polycarbonate (6mm) | $20 – $35 | Lower due to lightweight and ease of handling (up to 40% less than glass) | $0.50 – $2 | 15-25 year lifespan, 80% less maintenance cost than aluminum, good impact resistance and thermal insulation reducing energy costs |

| Tempered Glass (6mm) | $45 – $70 | Higher due to fragility and specialized framing required | $3 – $7 | Most expensive upfront, moderate maintenance, heavy and fragile |

| Aluminum Metal | $25 – $50 | Similar to polycarbonate but heavier, installation cost higher | $5 – $10 | Corrosion resistance but higher maintenance than polycarbonate |

*Tip: Facaplex polycarbonate roofing panels combine strength, insulation, and affordability, making them a smart alternative to both glass and metal for modern roofing needs.

Polycarbonate sheets installation and maintenance

Installation process

Facaplex polycarbonate sheets installation follows a clear set of steps to ensure long-lasting performance. Installers should always identify the UV-protected side and place it facing upward. This protects the material from sun damage. The ribs of the sheets must run along the slope of the roof to allow water drainage.

- Place the UV-protected side facing the sky.

- Align the ribs with the roof slope.

- Join sheets along their length using H-profiles. These can be aluminum or polycarbonate and help prevent leaks.

- Seal the top edge with solid aluminum tape to block water and dust.

- Apply vented aluminum tape to the bottom edge. This allows condensation to drain and keeps out insects.

- Close the top and bottom edges with U-profiles after taping.

- Secure the sheets to the frame using screws with neoprene washers. This prevents water from entering and spreads out the pressure.

- Drill holes slightly larger than the screw diameter. This step allows for thermal expansion and prevents cracks.

- For H-aluminum profiles, screw the base to the frame and snap on the cap.

- For one-piece polycarbonate H-profiles, secure sheets directly with screws and washers.

*Tip: Always remove the protective film after installation to avoid trapping moisture.

Installers should avoid common mistakes such as placing the UV side downward, over-tightening screws, or skipping expansion gaps. Proper framing support and careful handling prevent warping and scratches.

Maintenance tips

Facaplex polycarbonate roofing requires simple care to maintain its clarity and strength. Regular cleaning with mild soap and water removes dirt and debris. Avoid harsh chemicals or abrasive cleaners, as these can damage the surface. Use a soft cloth or sponge for best results.

- Inspect the roof for loose fasteners or damaged seals every few months.

- Keep gutters and drainage areas clear to prevent water buildup.

- Store replacement sheets in a dry place to avoid moisture entrapment.

- Leave the protective film on until installation to prevent scratches.

Polycarbonate roofing does not rust or corrode, which keeps maintenance costs low compared to metal or glass. UV coatings on Facaplex sheets help prevent yellowing and material breakdown. With proper care, these sheets can last 20 years or more.

*Note: Choosing high-quality polycarbonate sheets with UV stabilizers, like those from Facaplex, ensures maximum durability and performance.

Conclusion

Facaplex polycarbonate roofing sheets stand out for their durability, UV resistance, and design flexibility. Builders and architects choose them for projects ranging from stadiums to greenhouses because they offer excellent insulation, high impact resistance, and a wide range of colors and shapes. These sheets help lower energy costs, support sustainable building goals, and simplify installation. Facaplex provides a reliable, cost-effective solution for modern roofing needs.

*Choosing Facaplex polycarbonate roofing sheets means investing in long-lasting performance and versatile design for any project.