When you choose polycarbonate thickness for building facades, you need to focus on several key factors. Structural strength, insulation, light transmission, weather resistance, and cost all play a role in how to choose the right thickness. Polycarbonate sheets come in a wide range of thicknesses, so you can match the sheets to your project needs.

Every project is different. Make sure you review your goals before you choose polycarbonate thickness for your facade. Polycarbonate sheets offer flexibility for many projects, but picking the right thickness ensures your sheets perform well.

Why Polycarbonate Thickness Matters

Structural Strength and Durability

You need to consider the structural strength of polycarbonate when choosing facade materials. Polycarbonate sheets offer impressive durability, making them a top choice for many outdoor projects. The thickness of the sheets affects how much weight and impact they can handle. Thicker polycarbonate provides better resistance to wind, hail, and other outdoor forces. You can rely on polycarbonate material properties to maintain strength over time. When you use polycarbonate for outdoor roofing, you get a high-quality glazing material that stands up to harsh conditions.

Insulation and Energy Efficiency

Polycarbonate sheets help you control heat transfer in your building. The thickness of the polycarbonate impacts its insulation properties. Thicker sheets trap more air, which improves energy efficiency. You can reduce heating and cooling costs by choosing the right polycarbonate thickness. Many polycarbonate sheets also include UV protection, which helps keep indoor spaces comfortable and protects interiors from sun damage. For outdoor roofing, this feature adds extra value by blocking harmful rays.

Light Transmission and Aesthetics

You can achieve different lighting effects with polycarbonate. The properties of polycarbonate allow you to control how much natural light enters your building. Thinner sheets let in more light, while thicker sheets diffuse light and reduce glare. You can use polycarbonate to create bright, welcoming spaces or to add privacy. The right thickness also affects the look of your facade, helping you meet both functional and design goals.

- Polycarbonate sheets come in a range of thicknesses, so you can match your needs for light, privacy, and style.

- Outdoor applications benefit from the flexibility and clarity that polycarbonate provides.

Key Factors to Choose Polycarbonate Thickness

Building Type and Application

You must always consider the type of building and the application when you choose polycarbonate thickness. Different projects require different solutions. For example, a greenhouse, a commercial facade, and a sports facility all have unique needs. The size of polycarbonate sheet you select will depend on the scale and function of your project.

- For small canopies or window glazing, you can use thinner polycarbonate sheets, such as 4mm or 6mm.

- For large-scale projects, like stadiums or shopping centers, you need thicker sheets, often 16mm or more.

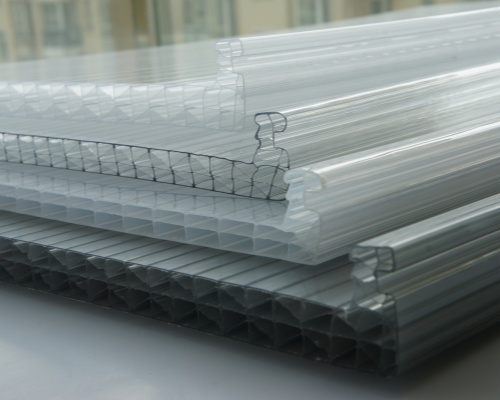

The type of polycarbonate sheet also matters. Multiwall sheets provide better insulation, while solid sheets offer higher impact resistance. Always match the size of polycarbonate sheets to the demands of your project.

Climate and Environmental Loads

Climate plays a big role in your decision. If your project is in an area with heavy snow, strong winds, or frequent storms, you need to choose polycarbonate thickness that can handle these loads. Thicker polycarbonate sheets resist bending and breaking under pressure.

- In hot climates, thicker sheets help block heat and UV rays.

- In cold regions, thicker sheets improve insulation and reduce heat loss.

The size of polycarbonate sheet you use should match the environmental challenges your building faces. Outdoor projects especially need careful planning to withstand weather extremes.

Load, Impact, and Support Spacing

You must think about the loads your polycarbonate sheets will face. This includes wind, snow, and even accidental impacts. The thickness of the sheet affects how much weight it can support without sagging or cracking.

- For areas with wide support spacing, you need thicker sheets to prevent deflection.

- For high-traffic zones or places at risk of impact, solid polycarbonate sheets offer the best protection.

The size of polycarbonate sheets also affects installation. Larger sheets may need extra support. Always check the manufacturer’s guidelines for the recommended support spacing based on the type of polycarbonate sheet and thickness.

Light and Noise Control

You can control both light and noise with the right polycarbonate. Thinner sheets allow more natural light to pass through, making them ideal for greenhouses or sunrooms. Thicker sheets diffuse light and reduce glare, which works well for offices or schools.

- Multiwall polycarbonate sheets provide better sound insulation than single-layer sheets.

- For privacy or noise reduction, choose polycarbonate thickness at the higher end of the range.

The size of polycarbonate sheet you pick will influence the overall lighting and acoustic comfort of your space.

Budget and Installation

Your budget will influence your choice, but you should not focus only on cost. Thicker polycarbonate sheets cost more, but they offer better durability and insulation. Thinner sheets are less expensive and easier to install, but may not last as long in demanding environments.

- For temporary or low-impact projects, you can use thinner sheets to save money.

- For permanent or high-value projects, invest in thicker sheets for long-term performance.

The size of polycarbonate sheets also affects installation time and labor costs. Larger sheets cover more area but may require special handling.

Common Polycarbonate Thicknesses and Their Uses

| Thickness (mm) | Typical Use Cases |

|---|---|

| 4mm – 6mm | Greenhouses, small canopies, window glazing |

| 8mm – 10mm | Skylights, partitions, medium facades |

| 16mm – 25mm | Commercial facades, roofing, sound barriers |

| 32mm – 50mm | Large-scale projects, high insulation needs |

You should always match the size of polycarbonate sheet and type of polycarbonate sheet to your project’s requirements. This approach ensures safety, comfort, and efficiency for any facade or outdoor application.

Polycarbonate Sheet Selection Guide

Assess Project Needs

Start your polycarbonate sheet selection by looking at your project’s unique requirements. Every building has different needs. You should ask yourself a few key questions:

- What is the main purpose of your facade?

- Do you need more natural light or better insulation?

- Will the sheets face heavy wind, snow, or impact?

- Is noise reduction important for your space?

- What is your budget for materials and installation?

You should write down your answers. This step helps you focus on what matters most for your project. If you plan to install a skylight, you need to think about both light transmission and weather resistance. For a commercial facade, you may want to balance strength, insulation, and appearance. By understanding your goals, you can choose the right polycarbonate sheets for your building.

Match Application to Thickness

Once you know your needs, you can match your application to the right polycarbonate thickness. Polycarbonate sheets come in many thicknesses. Each thickness works best for certain uses. Thinner sheets let in more light but offer less insulation. Thicker sheets provide better strength and energy savings.

Here is a practical table to help you choose the right polycarbonate sheets for your facade or other projects:

| Application | Recommended Thickness (mm) | Notes |

|---|---|---|

| Greenhouse | 4 – 6 | High light transmission, basic weather protection |

| Small Canopy/Window Glazing | 6 – 8 | Good for small areas, easy to install |

| Skylight | 10 – 16 | Optimum range for outdoors skylights, balances light and strength |

| Office Partition | 8 – 10 | Moderate sound control, privacy |

| Commercial Facade | 16 – 25 | Strong, energy efficient, good for large surfaces |

| Sound Barrier | 25 – 35 | High noise reduction, extra durability |

| Stadium/Industrial | 35 – 40 | Maximum strength, best for extreme conditions |

You should always check the manufacturer’s guidelines for each thickness. Some projects may need multiwall polycarbonate for better insulation. Others may require solid sheets for higher impact resistance. If you want to install a skylight, the optimum range for outdoors skylights is usually between 10mm and 16mm. This range gives you a good mix of light and weather protection.

Consult Experts or Manufacturers

You should always consult with experts or manufacturers before you make your final choice. Professionals can help you review your project details. They can suggest the best polycarbonate sheets for your needs. Many manufacturers offer technical support and can answer questions about installation, support spacing, and long-term performance.

If you have a complex project, expert advice can help you avoid costly mistakes. You can also ask for samples to compare light transmission and color options. When you work with professionals, you get peace of mind and better results for your facade.

Common Mistakes in Polycarbonate Sheet Selection

Overlooking Structural or Climate Needs

You might focus on appearance or price and forget about the structural needs of your building. If you choose the wrong thickness, your polycarbonate sheets may not handle wind, snow, or other loads. In areas with harsh weather, thin sheets can crack or bend. You should always check the climate and structural requirements before you select any material. A strong facade starts with the right thickness for your environment.

Ignoring Insulation or Light Requirements

Some people pick polycarbonate sheets without thinking about insulation or light needs. If you want to save energy, you need thicker sheets that trap more air. For spaces that need lots of daylight, thinner sheets work better. You should match the sheet thickness to your goals for light and temperature control. If you ignore these factors, you may end up with a space that is too hot, too cold, or too dark.

- Make a list of your insulation and lighting needs before you buy.

- Ask for samples to see how much light each sheet lets through.

Focusing Only on Cost

You may feel tempted to choose the cheapest option. However, picking polycarbonate sheets based only on price can lead to problems. Thin, low-cost sheets may not last long or provide enough protection. Over time, you might spend more on repairs or replacements. You should balance cost with performance and durability. Investing in the right thickness saves money and trouble in the long run.

Conclusion

Choosing the right polycarbonate thickness is key for building safety, energy efficiency, and appearance. Consider strength, insulation, light needs, and climate. Thicker sheets offer durability and insulation; thinner ones allow more light and cost less. Always consult experts to ensure the best fit for your project and long-lasting results.