A polycarbonate facade is valued for its strength, transparency, and modern appearance, making it a popular choice in both commercial and residential architecture. Beyond aesthetics, one of the most important considerations is how long these panels will last under real-world conditions. Factors such as material quality, UV protection, installation methods, and ongoing maintenance all play a role in determining durability. Understanding these influences helps architects, builders, and property managers make informed decisions when selecting and caring for polycarbonate facades.

Polycarbonate Facade Life Expectancy

Typical Lifespan

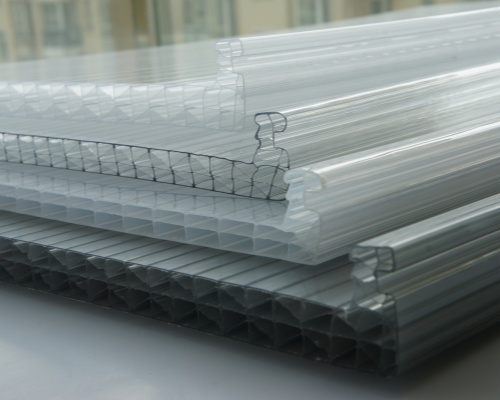

Polycarbonate panels usually last between 20 and 25 years. With proper care, their life expectancy can reach up to 30 years. Regular cleaning and routine inspections help maintain long-lasting performance.

Maintenance plays a key role in extending the life expectancy of polycarbonate. Removing dirt and debris prevents surface damage. Avoiding harsh chemicals also protects the panels from early aging.

Material Comparison

The life expectancy of polycarbonate compares well with other common facade materials. Glass panels often last over 30 years but may require more frequent repairs due to breakage. Acrylic panels usually last 15 to 20 years and can lose clarity faster than polycarbonate.

| Material | Typical Life Expectancy | Maintenance Needs | Impact Resistance | Transparency |

|---|---|---|---|---|

| Polycarbonate | 20-25 years (up to 30) | Low | High | High |

| Glass | 30+ years | Moderate | Low | High |

| Acrylic | 15-20 years | Moderate | Moderate | Moderate |

| Aluminum | 30+ years | Low | High | Opaque |

Polycarbonate offers strong impact resistance and good transparency. Aluminum panels last longer but do not provide the same clarity. Polycarbonate stands out for its balance of performance and long-lasting performance.

Factors Affecting Life Expectancy

Material Quality

Material quality plays a major role in how long a polycarbonate facade lasts. Manufacturers produce polycarbonate in different grades, and higher grades offer better strength and resistance to damage. Lower-grade polycarbonate may show signs of aging sooner and require replacement earlier.

UV Protection and Coatings

UV rays from sunlight can cause polycarbonate to degrade over time. Many panels include special UV-resistant coatings that protect the surface and slow down aging. These coatings help maintain clarity and prevent yellowing, which extends the life expectancy of the facade.

Installation Quality

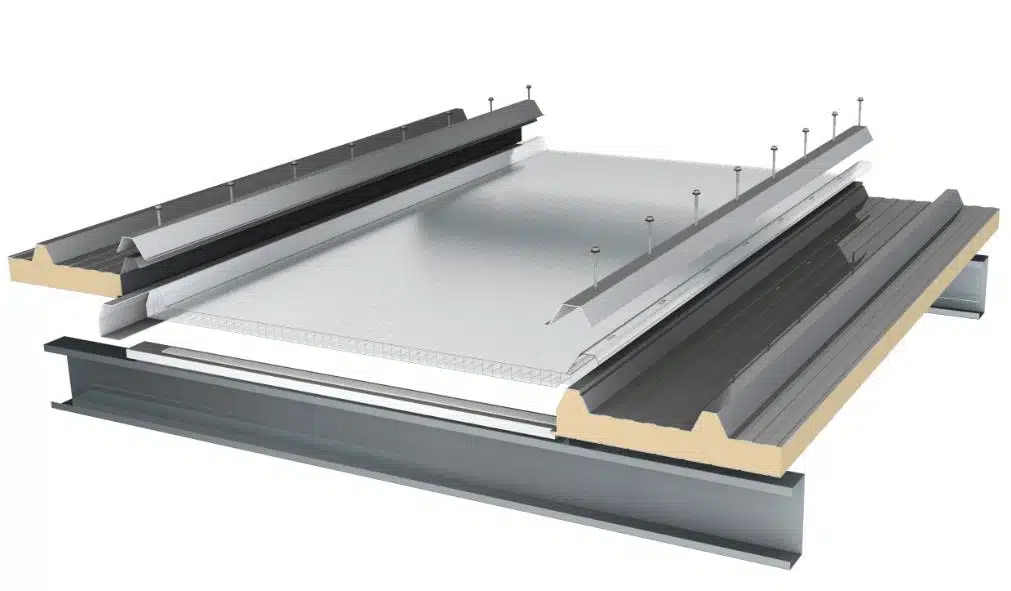

Proper installation ensures that polycarbonate panels stay secure and perform well. Incorrect installation can lead to stress on the panels, causing cracks or warping. Support structures must match the panel specifications to avoid unnecessary strain and damage.

Environmental Conditions

Environmental conditions affect polycarbonate durability. Areas with frequent extreme hot and cold weather can cause panels to expand and contract, which may lead to warping or cracking. High humidity, heavy rainfall, and strong winds also impact the facade’s lifespan.

Design Considerations for Extending the Lifespan

Light Management

Polycarbonate allows high daylight transmission while controlling glare and heat gain. Combining it with traditional glazing optimizes interior lighting without increasing cooling demand. Uniform light distribution is particularly important in sensitive environments such as schools, care homes, and healthcare facilities.

Sound Insulation

Acoustic performance can be enhanced with correct detailing and testing. Airborne and impact sound tests ensure compliance with regulations, reduce noise transmission, and improve occupant comfort.

Waterproofing and Drainage

Watertight facades prevent condensation and structural damage. Offsite mock-up testing confirms design performance, while onsite hose or spray-bar tests verify installation. Proper drainage paths and sealing reduce moisture-related issues and extend the system’s lifespan.

Thermal Performance

Thermally broken profiles prevent heat transfer and maintain U-values, reducing energy costs. Polycarbonate facades provide passive thermal control, helping keep interiors comfortable near perimeter zones.

Maintenance and Longevity

UV-protected coatings, correct sealing, and regular inspections prevent material degradation. Easy-to-clean and replaceable panels simplify upkeep, maintaining aesthetics and functionality over time.

By carefully addressing light, sound, water, and thermal performance, polycarbonate facades offer a sustainable, cost-efficient solution. Optimized design ensures decades of durability, occupant comfort, and energy savings, making them ideal for commercial and institutional buildings.

Signs of Aging or Degradation

Discoloration or yellowing

Polycarbonate facades can show signs of aging through discoloration. Yellowing often appears after years of exposure to sunlight. This change affects the appearance and may signal that the UV protection is wearing off.

Loss of impact resistance

Aging polycarbonate may lose its original strength. Panels that once resisted impacts can become brittle over time. This loss increases the risk of damage from hail, debris, or accidental contact.

Building users should check panels for flexibility and toughness. If panels feel weak or crack easily, replacement may be necessary.

Cracks & Warping

Cracks and warping often develop as polycarbonate ages. Temperature changes and weather stress the material. These issues can lead to leaks or reduced protection for the building.

It is important to check for visible cracks or areas where panels do not sit flat. Structural weakness can compromise the safety and function of the facade.

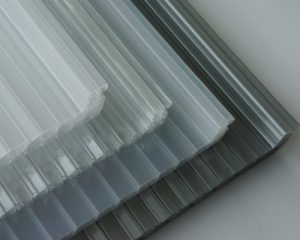

Reduced transparency or clarity

Old polycarbonate panels may lose their clear appearance. Dirt, scratches, and UV damage can make the surface cloudy. Reduced transparency affects both the look and the amount of natural light entering the building.

Warranties & Support

Most manufacturers offer warranties that cover defects, yellowing, and loss of impact resistance. Warranties usually last between 10 and 15 years. One should read warranty terms carefully to understand what is covered.

Engaging with manufacturers early helps resolve issues quickly. Manufacturers can provide advice, replacement panels, or repair options.

Durability Factors for Polycarbonate

UV and Weather Effects

Polycarbonate panels face many challenges from the environment. Sunlight, rain, wind, and temperature changes all affect how long polycarbonate lasts. UV rays from the sun can break down the surface of polycarbonate over time.

Weather plays a big role in the aging process. In areas with strong sunlight, polycarbonate may show signs of yellowing faster. Heavy rain and strong winds can also test the strength of polycarbonate facades.

Extreme weather, such as hail or snow, can cause cracks or dents. Polycarbonate resists impact better than many other materials, but repeated weather stress can still cause damage. Regular checks help spot early signs of wear from weather.

Polycarbonate with UV protection lasts longer in sunny climates. UV coatings block harmful rays and slow down the aging process. This helps keep the panels clear and strong even after years of weather exposure.

Installation Quality

Proper installation helps polycarbonate stand up to weather. Panels need strong support to handle wind and rain. If installed poorly, polycarbonate may warp or crack when the weather changes.

Installers must follow the manufacturer’s guidelines. This ensures the polycarbonate fits tightly and stays secure during storms or heavy weather. Good installation also reduces the need for repairs.

Polycarbonate requires little maintenance compared to other materials. Panels should be cleaned and checked for damage after severe weather. Simple care helps maintain the durability of the facade.

Maintenance and Care to Extend Lifespan

Routine cleaning practices

Routine cleaning helps polycarbonate roof panels last longer. Dust, dirt, and debris can build up on the surface. Use a soft sponge or cloth with mild soap and water to clean polycarbonate roof panels. Rinse with clean water and let the panels air dry. Clean polycarbonate roof panels at least twice a year for best results.

Avoid Harsh Chemicals

Harsh chemicals can damage polycarbonate roof panels. Avoid using strong cleaners like ammonia or bleach. Abrasive tools, such as steel wool or rough brushes, can scratch the surface of polycarbonate roof panels. Scratches make the panels cloudy and reduce their lifespan. Always use gentle cleaning tools and products designed for polycarbonate.

Protective coatings and treatments

Protective coatings help polycarbonate roof panels resist UV rays and weather damage. Some polycarbonate roof panels come with factory-applied UV coatings. These coatings slow down yellowing and keep the panels clear. Special treatments can also be applied to polycarbonate roof panels to boost protection. Regularly check if the coatings remain effective.

Inspections & Prevention

Inspect polycarbonate roof panels every few months. Look for cracks, warping, or signs of yellowing. Early detection helps prevent bigger problems. Tighten loose fasteners and replace damaged panels right away. Good installation and regular checks keep polycarbonate roof panels strong and safe.

Proper care, cleaning, and inspections help polycarbonate roof panels reach their full lifespan. Those who follow these steps protect their investment and keep buildings looking great.

- Polycarbonate facades often last 20 to 25 years, with proper care extending their lifespan.

- Key durability factors include material quality, UV protection, and installation standards.

- Manufacturer warranties add value and support long-term performance.

Conclusion

Choosing polycarbonate facades means investing in a material that combines modern aesthetics with long-lasting performance. Its durability, impact resistance, and clarity make it a standout option for both commercial and residential projects. By selecting quality panels and following proper maintenance, you ensure your building stays visually striking and structurally resilient for decades.