Selecting the right thickness for polycarbonate panels greatly impacts performance and longevity. People often compare polycarbonate versus glass, but polycarbonate offers better strength and insulation when choosing polycarbonate sheet for projects. A polycarbonate sheet overview shows that polycarbonate sheeting provides flexibility, light transmission, and cost savings, making buying polycarbonate sheet a smart choice for many applications.

Choosing the right thickness for polycarbonate panels depends on the project. The table below gives a quick guide for common uses. This helps users select the best sheet for their needs.

| Application | Recommended Thickness | Example Use Case |

|---|---|---|

| Greenhouses | 4mm, 6mm, 8mm | 4mm for small polycarbonate greenhouse, 6mm for glass replacement, 8mm+ for year-round use |

| Roofing | 8mm, 10mm, 16mm | 8mm for patio covers, 10mm for residential roofs, 16mm for heavy snow areas |

| Windows | 6mm, 8mm | 6mm for interior windows, 8mm for exterior windows |

| Skylights | 10mm, 16mm | 10mm for standard skylights, 16mm for high insulation needs |

| Partitions | 4mm, 6mm | 4mm for office dividers, 6mm for sound reduction |

Greenhouses

A polycarbonate greenhouse often uses 4mm sheet for hobby or starter models. Larger or commercial greenhouses benefit from 6mm or 8mm panels. Thicker polycarbonate improves insulation and durability, especially in colder climates.

Roofing

Polycarbonate roofing requires careful selection of thickness. An 8mm sheet works well for patios or pergolas. For areas with heavy rain or snow, 10mm or 16mm polycarbonate panels provide extra strength and protection.

Windows

Polycarbonate sheet serves as a strong alternative to glass in windows. A 6mm sheet fits most interior window needs. Exterior windows or those exposed to impact should use 8mm polycarbonate for added safety.

Skylights

Skylights need panels that balance light and insulation. A 10mm polycarbonate sheet allows good light transmission while keeping heat loss low. For energy efficiency, 16mm panels offer better insulation in skylight applications.

Partitions

Partitions in offices or homes often use 4mm polycarbonate sheet for easy installation. For more privacy or sound control, a 6mm sheet works better. Polycarbonate panels in these thicknesses remain lightweight and easy to handle.

Key Factors for Choosing Right Thickness

Application Type

The right thickness for polycarbonate panels depends on the project. Greenhouses, roofing, windows, and partitions each require a specific sheet thickness. For replacements, always match or exceed the original material thickness to maintain safety and performance.

Insulation Needs

Polycarbonate panels provide different levels of insulation based on their thickness. Thicker sheet options trap more air, which helps keep heat inside during winter and outside during summer. This makes thicker polycarbonate a better choice for energy efficiency in homes and greenhouses.

Light Transmission

Polycarbonate panels allow light to pass through, but the amount changes with thickness. Thinner sheet panels let in more light, which works well for greenhouses or skylights. Thicker polycarbonate reduces light transmission but increases impact resistance and insulation.

Structural Support

The right thickness helps polycarbonate panels handle wind, snow, and other loads. Thicker sheet panels offer better impact resistance and can span longer distances without bending. For areas with heavy weather or high impact risk, thicker polycarbonate is essential.

Budget

Budget plays a big role in choosing polycarbonate sheet thickness. Thicker panels cost more but last longer and provide better impact resistance. Buyers should balance the need for durability and insulation with the available budget to select the right thickness.

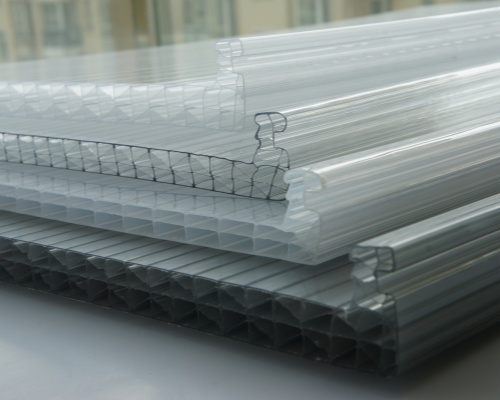

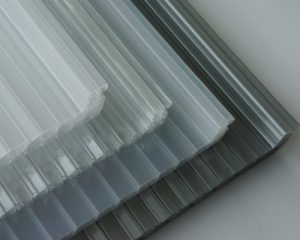

Polycarbonate Panels Thickness Options

4mm Panels

4mm polycarbonate panels work well for indoor projects. People use this thickness for partitions, small greenhouses, and craft projects. The sheet remains lightweight and easy to cut, making installation simple.

6mm Panels

6mm polycarbonate panels offer more strength and insulation than thinner options. This thickness fits interior windows, larger partitions, and greenhouses in cooler climates. The sheet resists minor impacts and handles moderate weather.

- 6mm polycarbonate works for glass replacement in windows.

- The sheet balances cost and durability for many indoor and outdoor uses.

8mm and 10mm Panels

8mm and 10mm polycarbonate panels provide strong protection and better insulation. These thicknesses suit roofing, exterior windows, and greenhouses used year-round. The sheet withstands wind, rain, and moderate snow loads.

People choose 8mm polycarbonate for patio covers and 10mm for residential roofs. The sheet also reduces heat loss and improves energy efficiency.

16mm and Up

16mm polycarbonate panels deliver maximum insulation and strength. This thickness fits commercial roofing, skylights, and greenhouses in harsh climates. The sheet supports heavy snow and strong winds.

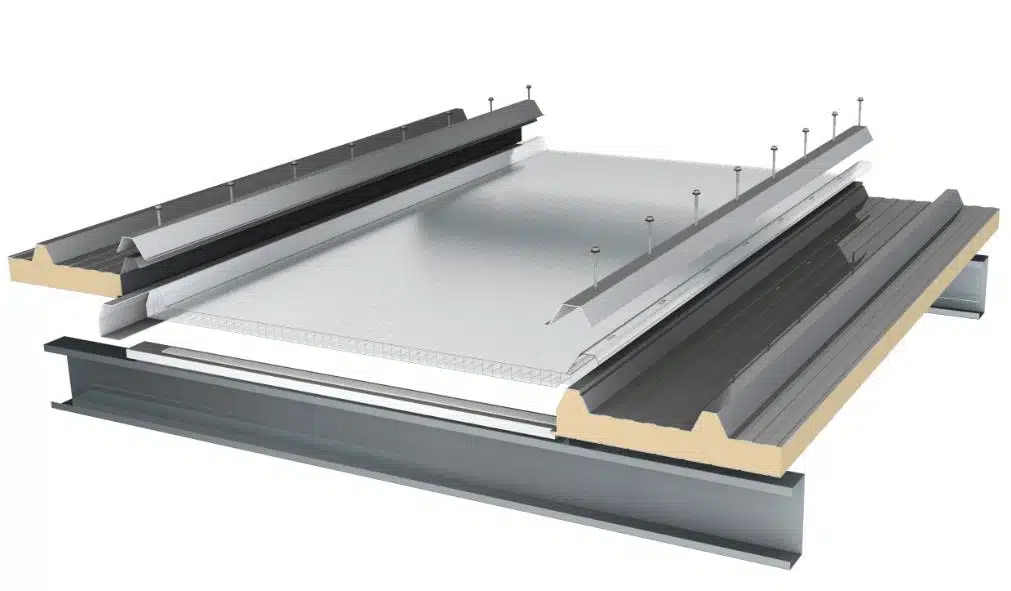

Best Thickness of Polycarbonate Roofing

Choosing the best thickness of polycarbonate roofing depends on the type of building, climate, and insulation needs. Polycarbonate offers strong protection and light transmission for both homes and businesses. The right sheet thickness ensures safety, durability, and energy efficiency.

Residential Roofing

Polycarbonate is often selected for patios, carports, and sunrooms. An 8mm sheet works well for mild climates and areas with light rain. For regions with heavy snow or strong winds, a 10mm sheet provides better strength and insulation.

A thicker polycarbonate sheet helps reduce heat loss and noise. Many people prefer 10mm polycarbonate roof sheets for year-round comfort. The sheet remains lightweight, making installation easier for residential projects.

Commercial Roofing

Commercial buildings need polycarbonate panels that handle larger spans and higher loads. A 16mm sheet offers excellent insulation and can support heavy snow or wind. This thickness also improves energy efficiency in warehouses, factories, and greenhouses.

Some commercial spaces use 25mm polycarbonate for maximum durability. Thicker panels last longer and require less maintenance. The sheet also helps control indoor temperatures, which lowers energy costs.

| Building Type | Recommended Thickness | Key Benefit |

|---|---|---|

| Residential | 8mm, 10mm | Easy install, good comfort |

| Commercial | 16mm, 25mm | High strength, insulation |

Selecting the right polycarbonate sheet thickness protects against weather and extends the life of the roof. The best thickness of polycarbonate roofing balances cost, strength, and insulation for each project.

Common Mistakes with Polycarbonate Sheeting

Too Thin for Load

Many people choose polycarbonate sheeting that is too thin for their project. Thin polycarbonate sheeting may bend or break under heavy snow or strong wind. For example, a 4mm sheet cannot support the weight of snow on a roof, while thicker polycarbonate sheeting can handle the load.

Overpaying for Thickness

Some buyers think the thickest polycarbonate sheeting is always best. They spend extra money on thick polycarbonate sheeting when a thinner sheet would work. For instance, a 16mm polycarbonate sheet is not needed for a small indoor partition.

A good rule is to match the thickness of polycarbonate sheeting to the project’s needs. This saves money and avoids waste.

Ignoring Insulation

Insulation is important for many projects using polycarbonate sheeting. Thin polycarbonate sheeting does not keep heat in or out very well. Greenhouses and skylights need polycarbonate sheeting with enough thickness to provide good insulation.

Skipping Support Needs

Polycarbonate sheeting needs proper support to last. Some people use polycarbonate sheeting without enough framing or bracing. Unsupported polycarbonate sheeting can sag or crack, even if the sheet has the right thickness.

Installers should always follow guidelines for supporting polycarbonate sheeting. Good support extends the life of polycarbonate panels and keeps the sheet looking new.

How to Decide on the Right Thickness

Selecting the right thickness for polycarbonate panels involves several steps. This guide helps users make confident choices for any project. Each step focuses on a key factor that affects performance and cost.

Define Project

Start by identifying the purpose of the polycarbonate installation. Consider if the sheet will be used for roofing, windows, partitions, or a greenhouse. The project type determines the basic requirements for polycarbonate panels.

Assess Demands

Evaluate the environmental and structural demands. Think about weather conditions, expected loads, and insulation needs. For example, a polycarbonate sheet on a roof in a snowy area needs to support heavy weight and provide good insulation.

Match to Thickness

Refer to the quick reference table for recommended thicknesses. Choose a polycarbonate sheet that meets or exceeds the demands listed. For high insulation, select a thicker polycarbonate panel. For indoor partitions, a thinner sheet often works well.

Check Budget

Review the cost of each polycarbonate sheet option. Thicker panels usually cost more but offer better performance. Balance the need for the right thickness with available funds. Avoid overspending on unnecessary thickness for simple projects.

- Compare prices for different polycarbonate sheet thicknesses.

- Choose the best option that fits both project needs and budget.

Conclusion

Selecting the proper polycarbonate thickness shapes the success of your project. Thicker panels provide better insulation, durability, and impact resistance, ensuring long-term performance. Whether for roofing, partitions, skylights, or greenhouses, matching the panel to your specific needs saves money and prevents errors. Always review requirements carefully and seek guidance from professionals or suppliers when necessary to ensure your project starts off on the right foot.