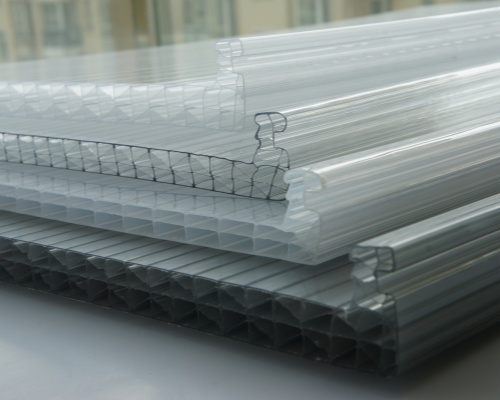

The main difference between twin wall polycarbonate and multiwall polycarbonate lies in the number of layers. Twin-wall polycarbonate features two layers separated by an air gap, which helps improve insulation and strength. Multiwall polycarbonate contains three or more layers, offering even better insulation and durability for demanding projects.

These differences affect performance in greenhouses, roofing, and insulation, making the right choice important for each application.

What Is Twin Wall Polycarbonate?

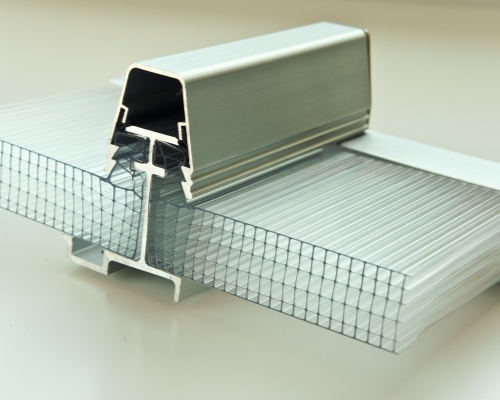

Structure and Layers

Twin-wall polycarbonate features two parallel layers of polycarbonate separated by a hollow space. This design creates an insulating air gap between the layers. The structure makes twinwall polycarbonate lightweight yet strong.

The air gap in twinwall polycarbonate helps reduce heat loss. It also provides some sound insulation. The rigid layers add strength and resist impact better than single-layer polycarbonate sheeting.

Twinwall polycarbonate sheets often come in standard thicknesses. These sheets are easy to cut and install. Many people choose twinwall for its balance of insulation and light transmission.

Common Uses

Twinwall polycarbonate sheeting works well for greenhouses. The material allows enough sunlight for plants while keeping heat inside. Many gardeners use twinwall polycarbonate sheets for cold frames and garden cloches.

Builders often select twinwall polycarbonate for patio covers and carports. The sheets protect against rain and hail. Twinwall also appears in skylights and porch roofing because it diffuses light and reduces glare.

Some people use twinwall polycarbonate for interior partitions. The panels offer privacy while letting light pass through. Twinwall remains a popular choice for projects that need both strength and insulation.

What Is Multiwall Polycarbonate?

Structure and Layers

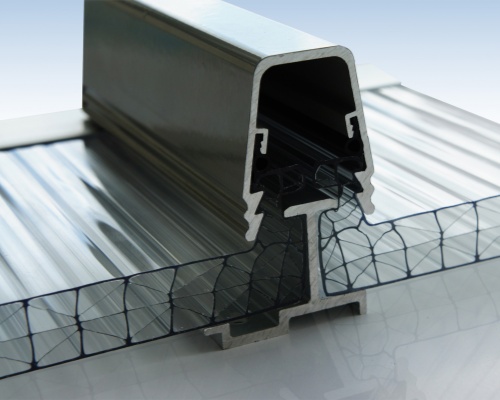

Multiwall polycarbonate features three or more layers of polycarbonate sheets. These layers create multiple air gaps between them. The extra layers give multiwall polycarbonate better insulation than twin wall sheets.

Manufacturers design multiwall sheets with different thicknesses and structures. Some sheets have a honeycomb or X-pattern inside. These patterns help increase strength and reduce heat loss.

Multiwall polycarbonate weighs more than twin wall sheets. The extra layers add durability and make the panels more rigid. This structure helps the material resist impacts and harsh weather.

Common Uses

People use multiwall polycarbonate in projects that need high insulation. Greenhouses with multiwall panels keep heat inside better during cold months. Builders also use multiwall polycarbonate for roofing in commercial buildings.

Multiwall panels work well for skylights and covered walkways. The extra layers help block UV rays and reduce glare. Some schools and sports centers use multiwall polycarbonate for walls and partitions.

Multiwall polycarbonate suits areas with extreme weather. The panels protect against hail, wind, and heavy rain. Many architects choose multiwall for energy-efficient buildings.

Common applications for multiwall polycarbonate:

-

- Greenhouses in cold climates

- Commercial roofing

- Skylights and canopies

- Indoor partitions in public spaces

Twinwall vs. Multiwall Polycarbonate

Insulation

Twin-wall polycarbonate provides basic insulation with its two-layer design. The air gap between the layers helps slow down heat transfer. Twinwall polycarbonate works well for mild climates but does not offer the superior insulating properties of multiwall.

Multiwall polycarbonate features three or more layers. These extra layers create multiple air gaps. This structure gives multiwall excellent thermal insulation, making it a better choice for cold climates or energy-efficient buildings.

When comparing twinwall vs. multiwall polycarbonate, multiwall stands out for insulation. The thicker and more complex structure of multiwall reduces heat loss more effectively. Many people choose multiwall for greenhouses or roofs where temperature control matters most.

Strength

Twin-wall polycarbonate offers good impact resistance. The two rigid layers make it stronger than single-layer sheets. Twinwall polycarbonate can handle moderate weather and light impacts.

Multiwall polycarbonate increases strength with each added layer. The extra layers and internal structure help it resist heavy impacts, hail, and strong winds. Multiwall panels often last longer in harsh environments.

The twin-wall vs multiwall comparison shows that multiwall is more durable. Multiwall polycarbonate is ideal for areas with extreme weather or where extra protection is needed. Twinwall works well for less demanding conditions.

Light Transmission

Twinwall polycarbonate allows a high level of light to pass through. This makes it a popular choice for greenhouses and skylights. Twinwall provides ideal light transmission for most plants and indoor spaces.

Multiwall polycarbonate lets in less light as the number of layers increases. The extra layers scatter and diffuse sunlight more. Multiwall is better for spaces that need softer, diffused light and less glare.

In the twinwall vs. multiwall polycarbonate debate, light transmission is a key factor. Twinwall is best when maximum sunlight is needed. Multiwall suits projects where glare reduction and insulation are more important.

| Feature | Twin-wall Polycarbonate | Multiwall Polycarbonate |

|---|---|---|

| Insulation | Moderate | Superior |

| Strength | Good | Excellent |

| Light Transmission | High | Moderate to Low |

Twin-Wall Polycarbonate: Pros and Cons

Advantages

Twinwall polycarbonate offers a strong balance of durability and light transmission. Many builders choose twinwall for its lightweight structure, which makes installation easy. The two-layer design provides moderate insulation, helping to keep spaces warmer in cooler months.

- Twinwall polycarbonate resists impacts from hail and debris.

- The material allows high levels of natural light, which benefits greenhouses and sunrooms.

- Twinwall sheets are easy to cut and fit into different project sizes.

Twinwall panels also provide some sound insulation. This feature helps reduce noise in busy areas. Many people find twinwall polycarbonate to be a practical solution for both indoor and outdoor uses.

Limitations

Twinwall polycarbonate does not offer the highest level of insulation. In very cold climates, heat can escape more easily compared to multiwall polycarbonate. The two-layer structure limits its ability to block extreme temperatures.

- Twinwall may not last as long in harsh weather as thicker multiwall panels.

- The material can show scratches or clouding over time if not maintained.

- Twinwall polycarbonate provides less strength than multiwall sheets in heavy-duty applications.

Twinwall polycarbonate works best for mild climates and moderate weather. It may not suit every project, especially those needing advanced protection or energy efficiency.

Multiwall Polycarbonate: Pros and Cons

Advantages

Multiwall polycarbonate offers excellent insulation. The multiple layers trap air and slow heat transfer. This feature helps buildings stay warmer in winter and cooler in summer.

Multiwall panels resist impacts from hail, wind, and debris. The structure makes them strong and durable. Many architects choose multiwall for areas with harsh weather.

Multiwall polycarbonate diffuses sunlight well. The extra layers reduce glare and create soft, even light. Greenhouses benefit from this effect because plants receive gentle light.

Multiwall suits many applications. Builders use it for roofing, skylights, and partitions. The panels also block harmful UV rays, protecting people and plants.

Limitations

Multiwall polycarbonate costs more than twinwall. The extra layers and strength increase the price. Some projects may need to balance budget and performance.

Multiwall panels weigh more than twinwall sheets. The added weight can make installation harder. Builders may need extra support for large roofs or walls.

Multiwall polycarbonate allows less light to pass through than twinwall. The layers scatter sunlight and reduce brightness. Some greenhouses may need more light for certain plants.

Multiwall panels require careful cleaning. Dirt can collect in the channels between layers. Regular maintenance keeps polycarbonate clear and effective.

Applications and Recommendations

Greenhouses

Many gardeners choose twinwall for greenhouse projects in mild climates. Twinwall polycarbonate provides good light transmission and moderate insulation. Multiwall panels work better for greenhouses in colder regions because they offer superior insulation and help maintain stable temperatures. For greenhouse glazing, multiwall polycarbonate keeps heat inside and protects plants from extreme weather. Both types resist impacts, but multiwall lasts longer in harsh conditions.

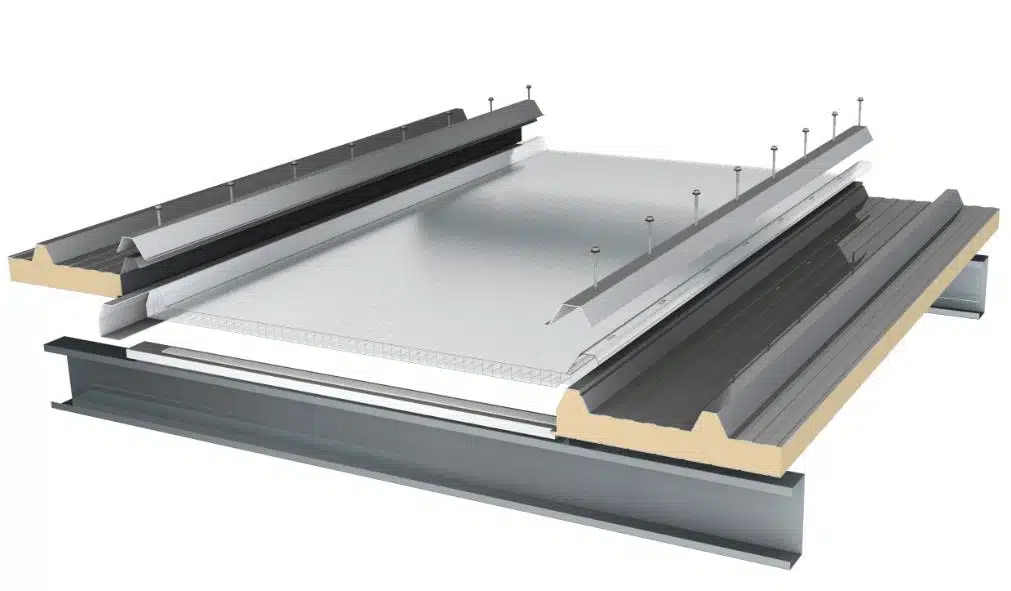

Roofing

Twinwall polycarbonate suits patio covers, carports, and porch roofs. It allows plenty of natural light and offers basic protection from rain and hail. Multiwall panels provide extra strength and insulation, making them ideal for commercial roofing or areas with heavy snow and wind. Builders often use multiwall for skylights and covered walkways where durability matters most.

- Multiwall polycarbonate reduces glare and diffuses sunlight.

- Twinwall works well for smaller, budget-friendly roofing projects.

Insulation

Multiwall polycarbonate stands out for insulation needs. The multiple layers trap air and slow heat transfer. This makes multiwall the best choice for projects that require temperature control, such as sunrooms or energy-efficient buildings. Twinwall polycarbonate offers some insulation but cannot match the performance of multiwall in extreme climates.

Other Uses

Twinwall polycarbonate works for interior partitions and privacy screens. It lets light pass through while providing separation. Multiwall panels suit public spaces, sports centers, and schools where extra strength and sound insulation are needed. Both types resist impacts, but multiwall offers better durability for high-traffic areas.

- Choose twinwall for lightweight, easy-to-install panels.

- Select multiwall for demanding environments or where long-term performance is important.

How to Choose Between Twinwall and Multiwall Polycarbonate

Key Factors

Choosing the right polycarbonate sheet depends on several important factors. Insulation needs come first for many projects. Multiwall polycarbonate provides better insulation because of its extra layers.

Light transmission also matters. Twin wall polycarbonate lets in more sunlight, which helps in greenhouses or sunrooms. Multiwall panels reduce glare and create softer light.

Strength is another key point. Multiwall polycarbonate stands up to harsh weather and heavy impacts. Twin wall works well for lighter-duty uses.

Budget can affect the final choice. Twin wall polycarbonate usually costs less and is easier to install. Multiwall panels cost more but last longer and offer better performance.

Quick Guide

Use this checklist to help decide which polycarbonate sheet fits your needs:

- Need high insulation for cold climates?

- Choose multiwall polycarbonate.

- Want maximum sunlight for plants?

- Pick twin wall polycarbonate.

- Building in an area with strong winds or hail?

- Select multiwall polycarbonate for extra strength.

- Working with a tight budget or small project?

- Twin wall polycarbonate is a good option.

- Prefer softer, diffused light indoors?

- Go with multiwall polycarbonate.

Comparison Table

| Feature | Twin Wall Polycarbonate | Multiwall Polycarbonate |

|---|---|---|

| Layers | Two | Three or more |

| Insulation | Moderate | High |

| Strength | Good | Excellent |

| Light Transmission | High | Moderate to Low |

| Weight | Lightweight | Heavier |

| Cost | Lower | Higher |

| Ease of Installation | Easy | Moderate |

| Durability | Good | Superior |

Conclusion

Twin-wall polycarbonate and multiwall polycarbonate differ in structure, insulation, and light transmission. Twin-wall polycarbonate works best for projects that need high light and easy installation. Multiwall polycarbonate provides better insulation and strength for demanding environments.

Before choosing polycarbonate, readers should review their needs for insulation, light, and strength. A careful comparison helps select the right material for greenhouses, roofing, or partitions. The right choice ensures long-lasting results and energy savings.