Corrugated Polycarbonate Panels Overview

What They Are

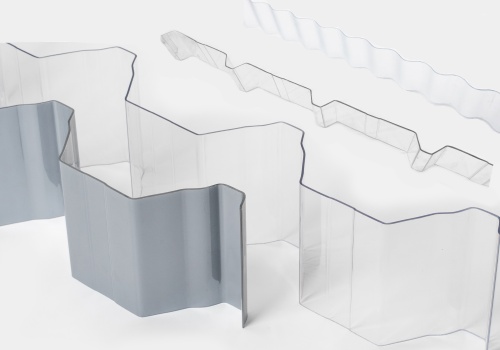

Corrugated polycarbonate panels use a wavy shape to add strength and flexibility. Manufacturers design these panels from a polycarbonate sheet, which is a type of tough plastic. People often choose polycarbonate panels for roofing, siding, and glazing because they offer high light transmission.

Polycarbonate panels come in different thicknesses and sizes. The corrugated design helps water run off easily. Many builders select polycarbonate panels for outdoor structures.

Material Properties

Polycarbonate panels have unique properties that make them popular. The material resists impact and does not crack easily. A polycarbonate sheet can bend without breaking, which helps during installation.

The panels weigh less than glass or metal. Polycarbonate panels do not rust or corrode, even in wet conditions. The surface blocks harmful UV rays and keeps its clarity over time.

| Property | Description |

|---|---|

| Impact Resistance | Withstands strong impacts |

| Flexibility | Bends without breaking |

| Weight | Lighter than glass or metal |

| Weather Resistance | Handles rain, wind, and sunlight |

| UV Protection | Shields against harmful rays |

Polycarbonate panels last for many years with minimal maintenance. Builders use polycarbonate sheet for projects that need durability and high light transmission. Corrugated polycarbonate panels combine these features for reliable performance.

Features of Polycarbonate Panels

Strength and Flexibility

Polycarbonate panels offer impressive strength. Builders rely on these panels because they are impact resistant and can handle heavy loads. The corrugated shape adds extra support, making polycarbonate panels suitable for roofing and siding.

Flexibility sets polycarbonate panels apart from other materials. Installers can bend and shape these panels without causing cracks. This feature allows polycarbonate panels to fit curved surfaces and unique designs.

Weather Resistance

Polycarbonate panels protect structures from harsh weather. The panels block rain, wind, and snow, keeping interiors dry and safe. Their weather resistance helps maintain clear visibility and prevents damage from sunlight.

Many builders choose polycarbonate panels for outdoor applications. The panels resist fading and yellowing, even after years of sun exposure. Polycarbonate panels also shield against harmful UV rays.

| Feature | Benefit |

|---|---|

| Weather resistance | Guards against rain and wind |

| UV protection | Prevents sun damage |

| Clarity retention | Maintains visibility |

Noncorrosive and Lightweight

Polycarbonate panels do not rust or corrode. This noncorrosive property makes them perfect for wet or humid environments. The panels stay strong and clear, even when exposed to moisture.

Lightweight construction allows easy handling and installation. Workers can lift and position polycarbonate panels without special equipment. The panels reduce overall building weight and simplify transport.

- Noncorrosive material extends the lifespan of polycarbonate panels.

- Lightweight design lowers labor costs and speeds up installation.

- Polycarbonate panels deliver durability and reliable performance in many settings.

Uses of Corrugated Polycarbonate Panels

Residential Uses

Homeowners use polycarbonate panels for many projects. These panels cover greenhouses, carports, and sheds. The panels allow sunlight to enter while protecting plants and vehicles from rain and wind.

Many people choose polycarbonate panels for roofing on patios and pergolas. The panels provide shelter and keep outdoor spaces bright. Some use these panels for pool covers, which help maintain water temperature and keep debris out.

Privacy screens made from polycarbonate panels offer both security and style. The panels block views and reduce noise from neighbors. Homeowners also install these panels for soundproofing in garages and workshops.

Commercial Uses

Builders use corrugated polycarbonate panels in commercial construction applications. These panels cover large greenhouses and nurseries, helping plants grow with natural light. Many commercial buildings use polycarbonate panels for roofing and siding because they resist impact and weather.

Retail stores and restaurants install polycarbonate panels for skylights and glazing. The panels brighten interiors and lower energy costs. Some businesses use these panels for hurricane protection, as they withstand strong winds and flying debris.

Polycarbonate panels also serve as privacy screens in offices and outdoor seating areas. The panels create quiet zones and block unwanted views. Builders prefer these panels for their durability and lightweight design.

| Commercial Application | Benefit |

|---|---|

| Greenhouses | High light transmission |

| Roofing | Weather resistance |

| Siding | Impact protection |

| Glazing | Energy savings |

| Privacy screens | Noise reduction |

Industrial Uses

Factories and warehouses rely on polycarbonate panels for many applications. The panels cover loading docks and walkways, protecting workers from rain and sunlight. Industrial buildings use polycarbonate panels for roofing and wall cladding because they last for years.

Some industries use polycarbonate panels for soundproofing and safety barriers. The panels absorb noise and shield workers from hazards. In hurricane-prone areas, these panels protect equipment and inventory from storm damage.

Polycarbonate panels also help control temperature and light inside large spaces. The panels reduce energy costs and improve working conditions. Industrial builders choose these panels for their strength and noncorrosive properties.

Comparing Panel Materials

Polycarbonate vs. Metal

Polycarbonate panels and metal panels serve similar purposes in construction. Metal panels offer high strength and resist fire. Polycarbonate panels provide impact resistance and allow light to pass through.

| Feature | Polycarbonate Panels | Metal Panels |

|---|---|---|

| Weight | Lightweight | Heavy |

| Light Transmission | High | None |

| Corrosion | Noncorrosive | Can rust |

| Flexibility | Flexible | Rigid |

| Installation | Easy | Requires tools |

Builders choose polycarbonate panels for projects that need natural light. Metal panels work well for structures that require extra security. Polycarbonate panels resist corrosion, while metal panels may rust over time.

Polycarbonate vs. Fiberglass and PVC

Fiberglass and PVC panels compete with polycarbonate panels in many applications. Fiberglass panels offer good strength and resist chemicals. PVC panels cost less and provide basic weather protection.

Polycarbonate panels last longer and resist impacts better than fiberglass and PVC. They also block harmful UV rays and keep their clarity. Fiberglass panels may yellow over time, and PVC panels can crack in cold weather.

- Polycarbonate panels provide better durability.

- Fiberglass panels resist chemicals but may discolor.

- PVC panels offer a budget-friendly option.

| Feature | Polycarbonate | Fiberglass | PVC |

|---|---|---|---|

| Impact Resistance | High | Moderate | Low |

| UV Protection | Yes | Limited | Limited |

| Lifespan | Long | Moderate | Short |

| Weight | Light | Light | Very Light |

| Cost | Moderate | Moderate | Low |

Practical Considerations

Lifespan

Corrugated polycarbonate panels last for many years. Most panels resist fading and yellowing, even after long exposure to sunlight. Builders often choose these panels for projects that need reliable performance over time.

| Panel Type | Typical Lifespan |

|---|---|

| Polycarbonate | 10–20 years |

| Fiberglass | 8–15 years |

| PVC | 5–10 years |

Regular cleaning helps maintain clarity and strength. Polycarbonate panels do not rust or corrode, which extends their useful life.

Cost

Polycarbonate panels offer a balance between price and performance. The initial cost is higher than PVC but lower than glass. Builders save money on installation because the panels are lightweight.

- Polycarbonate panels: Moderate price, long-term savings

- PVC panels: Low price, shorter lifespan

- Fiberglass panels: Moderate price, average durability

Installation Tips

Installers find polycarbonate panels easy to handle. The panels cut with basic tools and fit many designs. Always use the correct fasteners to prevent leaks.

- Place panels with the corrugation running down the slope for water runoff.

- Leave space for expansion during temperature changes.

- Seal edges to keep out moisture and debris.

Conclusion

Corrugated polycarbonate panels are a versatile building material known for their strength, flexibility, and weather resistance. These panels are commonly used in various residential, commercial, and industrial projects, providing reliable coverage and long-lasting performance.

Their unique wavy design not only adds structural strength but also allows for easy installation and efficient water runoff. As a popular choice for roofing, siding, and glazing, these panels are prized for their ability to offer both protection and natural light in a wide range of applications.