When choosing custom polycarbonate panels, buyers often look beyond basic durability. Key factors such as available sizes, cut-to-size options, thickness grades, colors, transparency levels, and fabrication possibilities all play an important role.

The following sections outline these options in detail, helping you understand how custom panels can match different project requirements.

Custom Polycarbonate Panels: Sizes

Standard Sizes

Manufacturers offer standard sizes for polycarbonate panels. Common dimensions include 24″ x 48″, 24″ x 96″, and 48″ x 96″. These sizes fit many construction and industrial projects.

Cut-to-Size Options

Custom Polycarbonate Panels can be cut to meet specific project needs. Suppliers use precision tools to create panels in almost any dimension. This option allows users to order panels that fit unique spaces or designs.

Benefits of cut-to-size panels:

- No need for on-site trimming

- Perfect fit for custom installations

- Less material waste

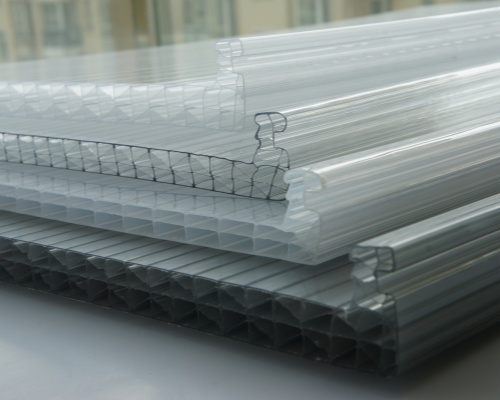

Thickness and Grades

Polycarbonate panels come in a range of thicknesses. Popular choices include 1/16″, 1/8″, 1/4″, and 3/8″. Thicker panels provide more strength and insulation.

| Thickness (inches) | Common Uses |

|---|---|

| 1/16 | Signage, displays |

| 1/8 | Glazing, partitions |

| 1/4 | Roofing, barriers |

| 3/8 | Safety enclosures |

Multiwall panels offer extra insulation and strength. These panels work well for greenhouses and large buildings. Custom Polycarbonate Panels are available in different grades to match project requirements.

Colors and Transparency

Clear Panels

Clear polycarbonate panels allow maximum light transmission. These panels work well for spaces that need natural light, such as greenhouses and skylights. People often choose clear panels for visibility and brightness.

Colored Panels

Colored polycarbonate panels add style and function to many projects. Manufacturers offer a wide range of colors, including blue, green, bronze, and white. Some users request unique colors to match branding or design themes.

Common uses for colored panels:

- Decorative partitions

- Privacy screens

- Signage

Colored panels can help control light and create visual interest in a space.

Transparency Levels

Custom Polycarbonate Panels come in different transparency levels. Options include fully transparent, translucent, and opaque panels. Transparent panels let in the most light, while opaque panels block light completely.

| Transparency Level | Light Transmission | Typical Use |

|---|---|---|

| Transparent | High | Glazing, windows |

| Translucent | Medium | Privacy, diffused light |

| Opaque | Low | Barriers, signage |

Manufacturers can adjust transparency by changing the panel’s color or finish. Customers may request specific levels of opacity for privacy or design needs.

Shapes and Fabrication

Flat and Curved Panels

Manufacturers produce polycarbonate panels in both flat and curved forms. Flat panels suit walls, partitions, and windows. Curved panels work well for canopies, awnings, and architectural features.

Geometric Shapes

Custom polycarbonate panels come in many geometric shapes. Suppliers can cut panels into rectangles, squares, circles, and triangles. Some projects require unique shapes, such as hexagons or trapezoids.

Common geometric shapes:

- Rectangle

- Square

- Circle

- Triangle

- Hexagon

These shapes allow designers to match specific project needs or create eye-catching patterns.

Edge Finishes

Edge finishes improve safety and appearance. Manufacturers offer several options, including smooth, beveled, and rounded edges. Smooth edges reduce the risk of injury during handling.

| Edge Finish | Description | Typical Use |

|---|---|---|

| Smooth | Flat and polished | Displays, glazing |

| Beveled | Angled and refined | Decorative panels |

| Rounded | Soft and curved | Safety enclosures |

Fabrication capabilities include drilling, routing, and engraving. These services help prepare panels for mounting, joining, or branding. Custom fabrication ensures panels fit perfectly and meet project requirements.

Key Features & Benefits

Impact Resistance

Custom Polycarbonate Panels offer outstanding impact resistance. These panels withstand strong forces without cracking or breaking. Many safety barriers and protective shields use polycarbonate because it resists damage from accidental hits or falls.

A comparison table shows how polycarbonate performs against other materials:

| Material | Impact Resistance | Typical Use |

|---|---|---|

| Polycarbonate | Very High | Safety shields |

| Acrylic | Moderate | Displays |

| Glass | Low | Windows |

Polycarbonate panels protect people and property in busy environments. Schools, factories, and sports facilities often choose this material for its durability.

UV Stability

Polycarbonate panels resist damage from sunlight. Manufacturers add UV stabilizers to prevent yellowing and loss of strength. These panels keep their clarity and color even after years of outdoor use.

UV stability helps maintain the appearance and performance of panels. Greenhouses, skylights, and outdoor signs benefit from this feature. Polycarbonate panels stay clear and strong under harsh sunlight.

Lightweight and Flexible

Polycarbonate panels weigh less than glass or metal. Workers can lift and install these panels with ease. The lightweight nature speeds up construction and reduces labor costs.

Flexibility allows panels to bend without breaking. Designers use curved panels for creative shapes and structures. Polycarbonate adapts to many installation methods and project needs.

Advantages of lightweight and flexible panels:

- Easy handling and transport

- Quick installation

- Creative design options

Custom Polycarbonate Panels combine strength, UV protection, and flexibility. These features make them a top choice for many industries.

Applications of Custom Polycarbonate Panels

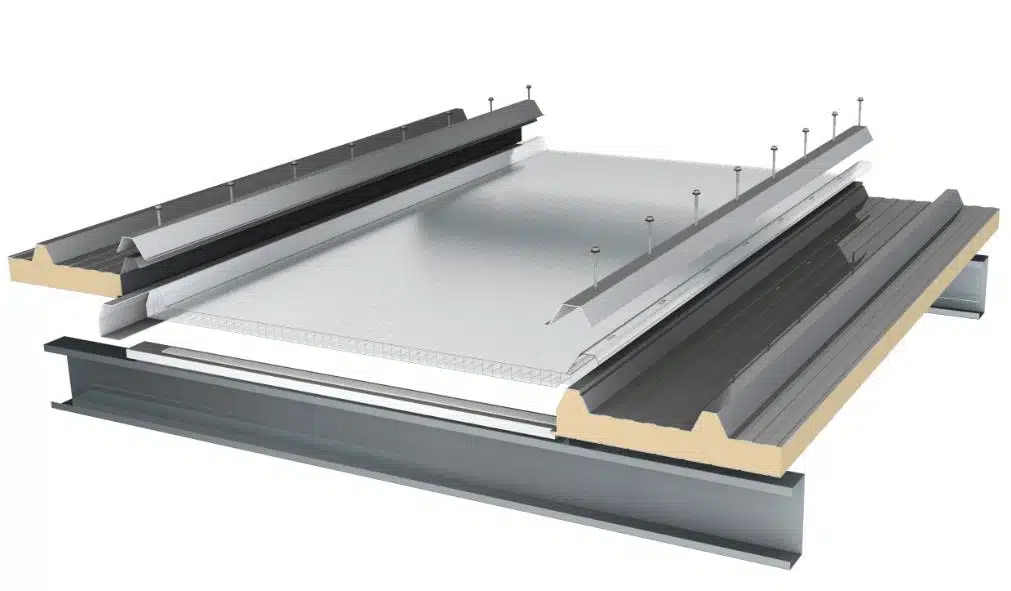

Building facades and roofing

Architects use Custom Polycarbonate Panels for building facades and roofing. These panels provide strong protection against weather and impacts. Designers select clear or tinted panels to control light and match the building’s style.

Panel thickness and shape affect insulation and appearance. Flat panels suit most walls, while curved panels work well for awnings and canopies. Edge finishes improve safety and create a polished look.

Greenhouses and agricultural structures

Growers choose polycarbonate panels for greenhouses and agricultural buildings. Clear panels allow sunlight to reach plants, while colored panels can filter light for specific crops. Translucent panels help diffuse light and prevent hotspots.

Panel size and thickness depend on the structure’s design and climate. Multiwall panels provide extra strength and insulation for larger greenhouses. Rounded edges and custom shapes help fit unique building layouts.

| Application | Recommended Panel Type | Benefit |

|---|---|---|

| Greenhouse roof | Clear multiwall | Maximum light, warmth |

| Side walls | Translucent single-wall | Diffused light |

| Animal enclosures | Opaque panels | Privacy, protection |

Industrial and safety enclosures

Factories and warehouses use polycarbonate panels for safety barriers and machine guards. These panels resist impacts and protect workers from flying debris. Opaque panels block visibility where privacy is needed.

Custom sizes ensure panels fit equipment and workspaces. Smooth or rounded edges reduce injury risks during installation. Colored panels can mark hazardous areas or guide traffic flow.

Factors to Consider When Ordering Custom Panels

Project requirements and budget

Every project has unique needs. The team should review the space, function, and environment before ordering panels. Budget planning helps select the right features without overspending.

Thickness options

Panel thickness affects strength, insulation, and weight. Thicker panels work best for safety barriers and roofing. Thin panels suit displays and partitions.

| Thickness | Best Use | Benefit |

|---|---|---|

| Thin | Displays, signage | Lightweight |

| Medium | Glazing, walls | Balanced |

| Thick | Roofing, barriers | Strong, safe |

Choosing the correct thickness ensures panels perform well in their intended application.

Installation methods and accessories

Installation methods vary by panel type and project. Some panels need screws, clips, or frames for secure mounting. Accessories like seals and trims improve appearance and weather resistance.

Common installation accessories:

- Mounting clips

- Edge trims

- Sealing strips

Proper installation keeps panels safe and extends their lifespan.

Manufacturer’s capabilities and delivery times

Manufacturers offer different customization services. Some can cut panels to exact sizes or shapes, while others provide special finishes. Delivery times depend on order size and complexity.

Steps to order custom panels:

- Gather project specifications (size, color, shape, thickness).

- Contact suppliers with detailed requirements.

- Review quotes and production schedules.

- Confirm order and arrange delivery.

Most suppliers provide estimated timelines. Simple orders ship faster than complex customizations. Planning ahead ensures panels arrive when needed.

Conclusion

Custom polycarbonate panels provide unmatched versatility, strength, and design flexibility for a wide range of applications. Available in standard and cut-to-size options, with choices in thickness, color, transparency, and shape, these panels meet both functional and aesthetic requirements. Their impact resistance, UV stability, and lightweight nature make them ideal for architectural projects, safety enclosures, agricultural structures, and more.

By considering factors such as panel thickness, installation methods, and manufacturer capabilities, users can select panels that deliver the perfect balance of durability, performance, and style. Whether for construction, industrial, or design purposes, custom polycarbonate panels remain a reliable solution that combines practicality with modern appeal.