The difference between solid and multiwall polycarbonate sheets lies in their structure and performance. Solid polycarbonate looks like glass and offers high clarity, while multiwall polycarbonate has layers that trap air for better insulation. Choosing the right polycarbonate matters because each type suits different needs for strength, insulation, and appearance.

Solid and Multiwall Polycarbonate Sheets Overview

What is a Solid Polycarbonate sheet

Solid polycarbonate looks like a flat, clear plastic sheet. It has a single, solid layer that resembles glass but weighs less. This type of polycarbonate offers high impact resistance and excellent clarity.

Solid polycarbonate sheet works well in places where people want a glass-like appearance but need more strength. Many people use it for windows, safety barriers, and protective covers. The material resists shattering and can handle rough treatment.

Solid polycarbonate also blocks harmful UV rays. It keeps its shape and clarity even after years of sun exposure. People choose it when they need a tough, clear material.

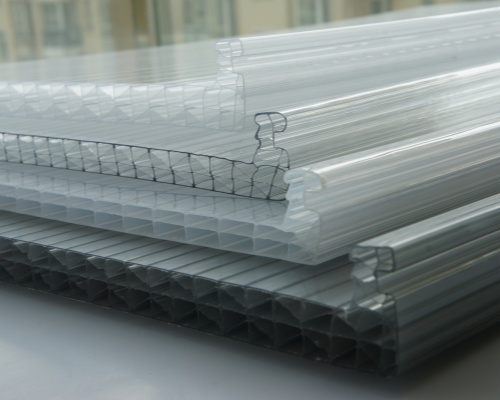

What is a Multiwall Polycarbonate sheet

Multiwall polycarbonate has two or more layers with air spaces between them. These layers form a structure that looks like a honeycomb or a set of channels. The trapped air gives multiwall polycarbonate better insulation than solid sheets.

Multiwall polycarbonate weighs less than solid polycarbonate. The air pockets make it lighter and easier to handle. This type of polycarbonate also reduces heat loss and helps control indoor temperatures.

Multiwall polycarbonate works well for greenhouses, skylights, and roofing. It lets in light but keeps heat inside. People often choose multiwall polycarbonate when they want energy savings and lightweight panels.

Solid vs. Multiwall Polycarbonate Sheets: Key Difference

Strength and Durability

Impact Resistance

Polycarbonate stands out for its impressive impact resistance. Solid polycarbonate sheets can withstand strong blows without cracking or breaking. This makes them a popular choice for safety barriers and protective panels.

Multiwall polycarbonate also offers good impact resistance. The layered structure helps absorb shocks, but it does not match the strength of solid sheets. People often use multiwall polycarbonate where some impact resistance is needed, but insulation matters more.

Both types of polycarbonate resist shattering much better than glass. This feature increases safety in public spaces and homes. Polycarbonate sheets help protect people and property from accidental damage.

Weather Performance

Polycarbonate performs well in harsh weather conditions. Both solid and multiwall sheets resist rain, snow, and wind. The material does not rust or corrode, even after years outdoors.

Many polycarbonate sheets include uv ray protection. This feature helps prevent yellowing and keeps the material clear over time. Uv ray protection also shields people and plants from harmful sun exposure.

Multiwall polycarbonate provides extra benefits in changing temperatures. The air pockets inside the sheets help reduce heat loss in winter and limit heat gain in summer. Solid polycarbonate offers less insulation but still protects against weather and sun.

Clarity and Light Transmission

Solid Polycarbonate Clarity

Solid polycarbonate offers exceptional clarity. This material allows up to 90% of visible light to pass through, which makes it look almost like glass. People often choose solid polycarbonate when they need clear views or want to maximize natural light.

Solid polycarbonate resists yellowing over time. The sheet maintains its transparency even after years of sun exposure. Many architects and builders use solid polycarbonate for windows, safety glazing, and display cases.

Multiwall Polycarbonate Light Transmission

Multiwall polycarbonate has a different structure. The layers and air gaps inside multiwall sheets scatter light as it passes through. This design creates a softer, diffused light that reduces glare.

Multiwall polycarbonate does not offer the same level of clarity as solid polycarbonate. However, it still lets in plenty of sunlight. Many people use multiwall polycarbonate for greenhouses, skylights, and roofing where even light distribution matters.

Multiwall polycarbonate also helps protect plants and interiors from harsh sunlight. The diffused light supports healthy plant growth and creates a comfortable indoor environment. Polycarbonate sheets with a multiwall design balance light transmission and insulation.

Insulation and Energy Efficiency

Multiwall Polycarbonate Insulation

Multiwall polycarbonate stands out for its excellent insulation properties. The unique structure of multiwall sheets traps air between layers. This trapped air acts as a barrier that slows down heat transfer.

People often choose multiwall polycarbonate for projects where energy efficiency matters. Greenhouses, sunrooms, and covered walkways benefit from this material. The insulation helps maintain stable temperatures inside these spaces.

Multiwall panels reduce heating and cooling costs. They keep warm air inside during winter and block excess heat in summer. This energy-saving feature makes multiwall a smart choice for eco-friendly buildings.

Solid Polycarbonate Insulation

Solid polycarbonate provides less insulation than multiwall sheets. The single-layer design does not trap air, so heat passes through more easily. This material works best where clarity and strength matter more than energy efficiency.

People use solid polycarbonate in places that need clear views and strong protection. Windows, safety barriers, and machine guards often use this material. While it blocks UV rays, it does not offer the same thermal benefits as multiwall.

Solid polycarbonate still protects against wind and rain. However, it cannot match the energy-saving performance of multiwall polycarbonate. For projects that require high insulation, multiwall remains the better option.

Weight and Handling

Installation Ease

Polycarbonate sheets offer different experiences during installation. Multiwall polycarbonate weighs less than solid polycarbonate. This lighter weight makes it easier for workers to lift and position panels, especially on roofs or large structures.

Solid polycarbonate feels heavier and more rigid. Workers may need extra help or equipment to move large sheets. Smaller projects with solid polycarbonate remain manageable, but larger installations can take more time and effort.

Multiwall polycarbonate often comes in larger sizes because of its lightness. Installers can cover more area with fewer seams. This feature helps reduce installation time and labor costs.

Support Needs

Support requirements differ between solid polycarbonate and multiwall polycarbonate. Solid polycarbonate needs strong framing because of its weight and rigidity. Installers must use sturdy supports to prevent sagging or bending over time.

Multiwall polycarbonate, with its lighter structure, needs less support. Builders can use wider spacing between supports without risking panel failure. This advantage can lower material costs and simplify the frame design.

The choice of support depends on the sheet type and the span length. For long spans or heavy loads, solid polycarbonate demands closer and stronger supports. Multiwall polycarbonate works well for projects that need lightweight panels and less structural reinforcement.

| Sheet Type | Weight | Support Spacing | Installation Difficulty |

|---|---|---|---|

| Solid Polycarbonate | Heavier | Closer | More challenging |

| Multiwall Polycarbonate | Lighter | Wider | Easier |

Polycarbonate sheets provide flexibility for many projects. Understanding weight and handling helps builders choose the right material for safe and efficient installation.

Cost and Value

Material Costs

The cost difference between solid and twinwall polycarbonate often shapes project budgets. Solid polycarbonate sheets usually cost more per square foot than twin-wall polycarbonate. This higher price comes from the solid structure and the clarity it provides.

Twin-wall polycarbonate uses less raw material because of its hollow design. This makes it more affordable for large projects. Many builders choose twin wall polycarbonate when they need to cover big areas without spending too much.

A simple price comparison shows that twin-wall polycarbonate offers a lower upfront cost. For projects like greenhouses or roofing, this can make a big difference. The lighter weight of twin wall polycarbonate also reduces shipping and handling expenses.

Long-Term Value

Material cost is only one part of the total investment. Long-term value depends on durability, maintenance, and energy savings. Solid polycarbonate lasts many years with little need for repairs. Its strength protects against impacts and harsh weather.

Twin-wall polycarbonate provides excellent insulation. This feature helps lower heating and cooling costs over time. Many greenhouse owners see energy savings that offset the initial purchase price.

For projects that need maximum clarity and strength, solid polycarbonate may justify the higher cost. For applications where insulation and budget matter most, twin-wall polycarbonate often delivers better value.

| Sheet Type | Upfront Cost | Insulation | Durability | Best Value For |

|---|---|---|---|---|

| Solid Polycarbonate | Higher | Low | Very High | Safety glazing, clear panels |

| Twin-wall Polycarbonate | Lower | High | High | Greenhouses, roofing, skylights |

How to Choose Between Solid and Multiwall Polycarbonate Sheets

For Insulation

Multiwall polycarbonate provides excellent insulation. The air pockets inside multiwall panels slow down heat transfer. Builders often select multiwall for greenhouses, sunrooms, and roofing where temperature control matters.

Solid polycarbonate does not insulate as well. The single-layer design allows more heat to pass through. People choose solid polycarbonate when insulation is less important.

For Clarity

Solid polycarbonate offers high clarity. The material looks almost like glass and allows most visible light to pass through. Architects use solid polycarbonate for windows, safety glazing, and display cases.

Multiwall panels scatter light. The layered structure creates a softer, diffused effect. Multiwall works best where even light distribution is needed, such as skylights or greenhouses.

| Sheet Type | Clarity Level | Best Use Cases |

|---|---|---|

| Solid Polycarbonate | Very High | Windows, displays |

| Multiwall | Moderate | Greenhouses, skylights |

For Durability

Polycarbonate resists impacts and harsh weather. Solid polycarbonate stands out for its strength. It protects against strong blows and does not shatter easily.

Multiwall polycarbonate also resists damage. The layered design absorbs shocks, but it does not match the strength of solid polycarbonate. Both types last for years outdoors.

For Budget

Multiwall polycarbonate costs less than solid polycarbonate. The hollow structure uses less material, which lowers the price. Builders often choose multiwall for large projects to save money.

Solid polycarbonate costs more because of its solid design and clarity. People select solid polycarbonate when they need maximum strength and transparency.

- Multiwall: Best for budget-friendly insulation and coverage.

- Solid polycarbonate: Best for projects needing clear, strong panels.

Conlcusion

The selection between solid and multiwall polycarbonate sheets affects clarity, insulation, and cost. Solid polycarbonate gives high clarity and strength, while multiwall polycarbonate offers better insulation and lower weight. When choosing, readers should match the sheet to their project’s needs. For clear views, solid polycarbonate works best. For energy savings, multiwall polycarbonate is the top choice. Always compare the difference between solid and multiwall options before making a decision.