Polycarbonate panels are widely used for roofing and siding due to their lightweight structure, high impact resistance, and excellent UV protection. While inherently durable, these panels can experience issues such as scratches, yellowing, or cracks if not properly cared for. Regular maintenance is key to preserving both their clarity and structural integrity, ensuring that they continue to perform effectively over time.

Maintaining polycarbonate panels involves routine inspections, gentle cleaning, and timely repairs. By following practical care strategies, Professionals can extend the lifespan of their panels, protect their investment, and keep their roofing or siding looking clear and strong for years to come. The following guide outlines essential tips and steps for long-term polycarbonate panel durability.

Understanding Polycarbonate Panels

Polycarbonate Properties

Polycarbonate offers high impact resistance and transparency. This material blocks harmful UV rays, which helps protect interiors and extends the life of polycarbonate roofing sheets. Manufacturers design polycarbonate to withstand harsh weather and resist yellowing from UV exposure.

Polycarbonate weighs less than glass but provides similar strength. It resists cracking from thermal expansion and impact. Many builders choose polycarbonate roofing sheets for their durability and ability to filter uv light.

Types of panels

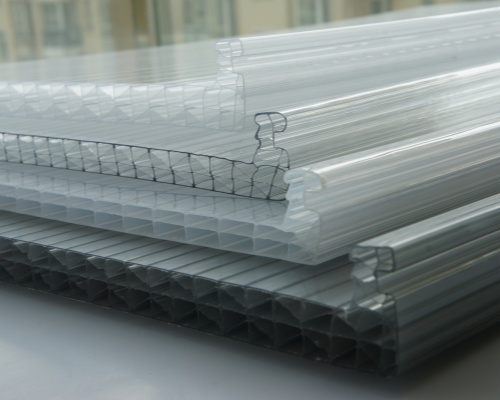

Solid polycarbonate panels are made of a single, uniform layer, offering maximum clarity and strength. They are highly durable and provide excellent protection against impacts and UV rays. Solid panels are ideal for applications where transparency is important, such as greenhouses, skylights, or decorative roofing. Their robust structure makes them resistant to cracking, while still being lightweight compared to glass.

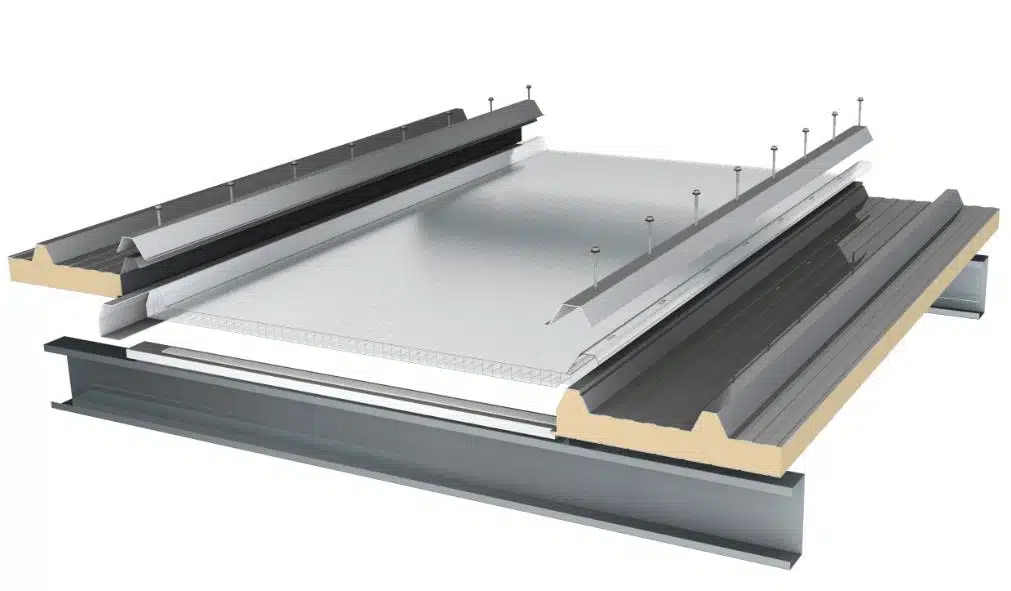

Multiwall polycarbonate panels consist of multiple layers separated by air gaps, which improve thermal insulation and energy efficiency. This design reduces heat transfer, keeping interiors cooler in summer and warmer in winter. Multiwall panels also offer enhanced strength and UV protection, making them suitable for commercial buildings, carports, or covered walkways. They are lightweight, versatile, and easy to install.

Corrugated polycarbonate panels have a wavy surface that increases structural strength and allows for efficient water runoff, making them ideal for roofing applications in areas with heavy rain or snow. These panels combine durability, impact resistance, and UV protection while offering a cost-effective solution for large surface coverage. Corrugated panels are commonly used for warehouses, patios, and industrial roofing.

| Panel Type | Structure | Main Benefit | UV Protection |

|---|---|---|---|

| Solid | Single layer | High clarity, strength | Yes |

| Multiwall | Layered, air gaps | Better insulation | Yes |

| Corrugated | Wavy surface | Water runoff, strength | Yes |

Polycarbonate roofing sheets come in these styles to match various building requirements. Each type blocks UV rays and provides long-lasting protection.

Common Issues Affecting Durability

Scratches and surface damage

Scratches often appear on polycarbonate panels when people use abrasive cleaners or rough cloths. These scratches can reduce clarity and weaken the surface, making the panels more vulnerable to further damage. Regular gentle cleaning helps in protecting from UV damage and keeps the panels looking new.

Discoloration from UV

Polycarbonate panels sometimes show yellowing or discoloration after long periods in sunlight. This change happens when the panels lose their ability to block harmful rays, which affects both appearance and performance. Protecting from UV damage by choosing panels with a UV-resistant coating helps maintain their clear look and durability.

A simple inspection every few months can catch early signs of yellowing. Replacing affected panels quickly ensures the structure stays strong and attractive.

Thermal & Impact Cracks

Cracks may develop in polycarbonate panels because of sudden temperature changes or strong impacts. These cracks can spread and reduce the panel’s strength. Proper installation allows for some movement, which helps prevent cracks and supports long-term durability.

Polycarbonate’s design resists many impacts, but regular checks and quick repairs keep the panels in top condition.

Inspecting Panels Regularly

Panel Checkup

Regular inspections help maintain polycarbonate panels and prevent costly repairs. They should inspect for damage such as cracks, leaks, and loose fittings at least once every season. A simple checklist makes the process easier:

- Look for visible cracks or chips on each panel.

- Check for water leaks around panel edges.

- Test all fasteners and fittings to ensure they stay secure.

Regular inspections enable early detection of problems. They can address minor issues before they become serious.

Repair & Replacement

When regular inspections reveal damage, action should be taken quickly. They can maintain polycarbonate panels by repairing small cracks with a clear sealant. For larger damage, replacing the affected section works best.

Follow these steps to repair or replace panels:

- Remove the damaged panel carefully.

- Clean the area and prepare a new polycarbonate sheet.

- Secure the new panel using proper fasteners.

Regular inspections and maintenance help extend the life of polycarbonate roofing or siding. They protect their investment and keep the structure safe.

Maintenance Tips for Long-Term Durability

Avoid High-Pressure Cleaning

High-pressure washing can damage polycarbonate roofing sheets and reduce their durability. Polycarbonate panels should be cleaned regularly using a soft sponge and mild soap. This method meets the requirements for cleaning polycarbonate and helps maintain polycarbonate panels without causing scratches.

Regular cleaning removes dirt and supports UV protection maintenance. These essential maintenance tips help extend the lifespan of polycarbonate roofing sheets and keep them looking new.

Securing Panels Safely

Strong winds and storms can loosen polycarbonate roofing sheets. Fasteners and fittings should be checked before severe weather. Securing panels tightly prevents leaks and protects the longevity of polycarbonate roofing sheets.

A simple checklist helps maintain polycarbonate panels and ensures roofing stays safe. Essential maintenance practices include inspecting for loose fittings and reinforcing weak spots. These maintenance tips help extend the lifespan of roofing and prevent costly repairs.

Storing spare panels correctly

Proper storage of spare polycarbonate roofing sheets increases their durability. Panels should be kept in a dry, shaded area to prevent yellowing and surface damage. Storing panels flat and away from direct sunlight protects uv-protective coatings.

Essential maintenance tips include labeling spare panels and checking them for cracks before installation. These steps help extend the lifespan of roofing and support essential maintenance tips for every project.

| Storage Tip | Benefit |

|---|---|

| Store flat and shaded | Protects coatings and clarity |

| Keep dry and clean | Prevents mold and debris |

| Inspect before use | Ensures durability |

Following these maintenance tips for polycarbonate roofing sheets supports long-term durability and effective maintenance.

Conclusion

Proper maintenance is essential to ensure polycarbonate panels remain durable, clear, and effective over time. By conducting regular inspections, gentle cleaning, and timely repairs, you can prevent common issues such as scratches, yellowing, and cracks caused by UV exposure, weather, or impact. Choosing the right type of panel—solid, multiwall, or corrugated—and handling it with care further enhances longevity.

Following these maintenance practices not only protects your investment but also extends the lifespan of roofing or siding, maintains UV protection, and keeps your structure looking its best. Consistent care ensures that polycarbonate panels continue to provide reliable performance and long-term durability for years to come.