You must consider every aspect of safety before choosing polycarbonate facades for your project. Ignoring safety risks can lead to costly repairs and endanger safety on-site. Always check how installation methods, material weaknesses, and maintenance needs may impact safety. Careful planning protects both your investment and the people who use the building.

What Are Polycarbonate Facades?

Brief Overview

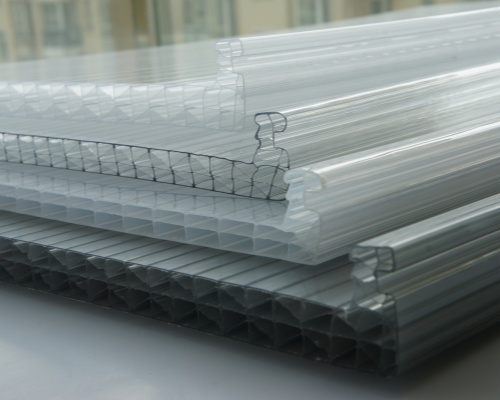

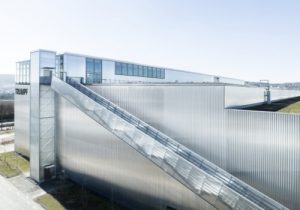

You see polycarbonate facades used in many modern buildings. These facades use polycarbonate sheets as the main exterior material.Polycarbonate is a lightweight, transparent plastic. You find it in many applications because it resists impact and weather.

The construction industry values polycarbonate for its strength and flexibility. You can shape polycarbonate sheets into curves or angles for creative designs.Polycarbonate sheets come in different thicknesses and finishes. You can choose clear, tinted, or textured options to control light and privacy.

You often see polycarbonate facades in schools, sports centers, and commercial buildings. The construction industry uses polycarbonate to create bright, energy-efficient spaces. Polycarbonate sheets allow natural light to enter while blocking harmful UV rays. You can improve comfort and reduce lighting costs with this material. The construction industry prefers polycarbonate for projects that need fast installation. You can cut and fit polycarbonate sheets on-site with basic tools.

Polycarbonate sheets resist shattering, so you can improve safety in high-traffic areas. You also get good insulation, which helps control indoor temperatures. You should know that polycarbonate facades offer a modern look and practical benefits. However, you must weigh these advantages against the disadvantages before making a decision.

Surface Scratching

Appearance Impact

You will notice that polycarbonate sheets scratch more easily than glass or metal. Even light contact with tools or cleaning brushes can leave visible marks on polycarbonate surfaces.

When you install polycarbonate facades in high-traffic areas, you risk frequent scuffs and scratches. These marks can quickly reduce the visual appeal of your building.

Scratches on polycarbonate sheets can catch and reflect light, making them more noticeable. Over time, the facade may look dull or worn, even if you clean it regularly.

If you want to maintain a pristine appearance, you must inspect polycarbonate sheets often and address any damage right away.

Durability Concerns

Surface scratching does not only affect looks. It also impacts the long-term durability of polycarbonate facades.When scratches accumulate, they can weaken the outer layer of polycarbonate sheets. This damage makes the material more vulnerable to cracking or further wear.You may find that deep scratches allow dirt and moisture to enter, which can speed up the aging process of polycarbonate sheets.

If you want to maximize durability, you must choose polycarbonate sheets with hard coatings. These coatings help resist scratches but do not make the material scratch-proof. You should also consider the location of your polycarbonate facade. Areas exposed to wind-blown debris or frequent contact will see faster wear and reduced durability.

Regular maintenance and careful cleaning can extend the durability of polycarbonate sheets, but you must accept that some surface scratching is unavoidable. When you plan your project, weigh the durability concerns against the benefits of polycarbonate. This step helps you avoid unexpected maintenance costs and keeps your facade looking its best.

Thermal Expansion

Warping Risks

You need to understand that polycarbonate expands and contracts with temperature changes. Polycarbonate sheets can warp if you do not allow for this movement during installation.When you expose polycarbonate to direct sunlight, the material heats up quickly. This heat causes polycarbonate sheets to grow in size. If you fix polycarbonate sheets too tightly, they cannot move freely. You may see buckling, bending, or even cracks as a result.

Installation Considerations

You must plan for thermal expansion when you install polycarbonate sheets. Always leave enough space at the edges of each sheet. Use special fasteners that allow polycarbonate to move as temperatures change. These fasteners help prevent stress on the sheets. You should avoid over-tightening screws or bolts. Tight fasteners can trap polycarbonate sheets and cause damage.

UV Degradation

Yellowing

You may notice yellowing on polycarbonate sheets after several years outdoors. Sunlight causes this change, especially when the material lacks strong uv resistance. Polycarbonate absorbs ultraviolet rays, which break down its surface over time. Yellowing reduces the visual appeal of your polycarbonate facade. You may see the color shift from clear to a dull yellow, which can make your building look older than it is.

Polycarbonate sheets with yellowing lose their modern, clean look. You may need to replace affected panels sooner than expected. If you want to slow down yellowing, choose polycarbonate sheets with high uv resistance. Regular inspections help you spot early signs of color change.

Loss of Clarity

You expect polycarbonate sheets to stay clear and bright. UV degradation can cause the surface to become cloudy or hazy. This loss of clarity affects how much natural light enters your building.

When polycarbonate loses clarity, you may notice less daylight and more shadows inside. The facade may also look less attractive from the outside.

Polycarbonate with poor resistance to UV rays will lose clarity faster. You should check the manufacturer’s data on uv resistance before you buy. If you see cloudiness or dull spots, you may need to replace the polycarbonate sheets. Regular maintenance helps you catch these issues early. Polycarbonate offers good resistance to many weather conditions, but UV degradation remains a key weakness. You must weigh this risk before choosing polycarbonate for your facade.

Impact Damage

Dents from Hail

You may expect polycarbonate to offer strong protection against weather. However, polycarbonate sheets can still suffer dents from hail. Even though polycarbonate has good impact resistance, large hailstones can leave visible marks. You might notice small dents or surface deformations after a severe storm. These dents can affect the appearance of your facade and reduce its value.

Polycarbonate sheets with dents may also lose some of their clarity. Light can scatter in unexpected ways, making the building look uneven. You should inspect polycarbonate sheets after every major hail event. Early detection helps you plan repairs before the damage spreads.

You should also consider the angle and placement of your polycarbonate facade. Sloped surfaces may deflect hail better than flat ones. Proper installation can help minimize the risk of impact damage.

Structural Integrity

Polycarbonate offers high impact strength, but repeated impacts can weaken the material over time. You may see cracks or splits develop if polycarbonate sheets face frequent blows. Impact resistance does not mean the material is indestructible. You must check for hidden damage, especially at joints and edges.

Polycarbonate sheets that lose structural integrity may allow water or air to enter the building. This can lead to leaks, drafts, or even mold growth. You should schedule regular inspections to catch these problems early. Replacing damaged polycarbonate sheets quickly helps maintain the safety and performance of your facade.

You can improve the lifespan of your polycarbonate facade by choosing quality materials and proper installation. Impact resistance remains a key benefit, but you must stay alert to the risks of dents and structural damage.

Fire Safety

Flammability

You must pay close attention to fire safety when you choose polycarbonate facades. Polycarbonate is a plastic material that can burn under high heat. You may notice that polycarbonate sheets can ignite faster than glass or metal. This risk makes fire safety a top concern for many building projects.

You can find polycarbonate sheets with fire-retardant additives. These products slow down the spread of flames but do not make the material fireproof. You should always check the fire safety rating before you select a product.If you install polycarbonate in areas with high fire risk, you increase the chance of rapid fire spread. You must plan for extra safety measures to protect people and property.

Building Codes

You need to follow strict building codes that address fire safety. Local codes often set limits on the use of polycarbonate facades in certain types of buildings. You may find that some codes require fire barriers or sprinkler systems for added safety.

You should review the fire safety classification of your chosen polycarbonate sheets. Many codes require materials to meet specific fire safety tests.If you ignore these rules, you risk fines or forced removal of non-compliant facades. You protect your investment and ensure safety by following all fire safety codes.You should always prioritize fire safety in your design and installation process. Careful planning and code compliance help you avoid costly mistakes and improve overall safety.

Chemical Sensitivity

Cleaning Agents

You need to pay close attention to the cleaning products you use on polycarbonate facades. Many common cleaners contain chemicals that can damage polycarbonate sheets. Some cleaning agents cause cloudiness or surface cracks. You may notice that polycarbonate loses its clarity after using harsh chemicals. Polycarbonate sheets have limited resistance to strong solvents. You should avoid products with ammonia, acetone, or alcohol.

Maintenance Risks

You face risks if you do not follow proper maintenance procedures for polycarbonate facades. Polycarbonate sheets can react badly to abrasive tools or rough scrubbing.

Scratches from improper cleaning reduce the resistance of polycarbonate to weather and UV exposure. You may see more rapid aging or yellowing as a result.

Polycarbonate sheets also lose resistance to impact if you use the wrong cleaning methods. Damaged surfaces become more vulnerable to cracks and leaks.

Installation Challenges

Joint Weakness

You must pay close attention to how you join polycarbonate sheets. Precise panel bonding is critical for a strong facade. If you do not align polycarbonate sheets correctly, you create weak points in the structure. These weak joints can fail under pressure or movement.

Water leaks are a common issue with polycarbonate facades. Improper installation of polycarbonate sheets often leads to water intrusion. You must seal all joints and edges carefully. Even a small gap between polycarbonate sheets can let in rainwater.

Noise Transmission

Rain and Hail Noise

You will notice that polycarbonate facades can amplify the sound of rain and hail. When rain hits polycarbonate sheets, the noise can become loud and distracting. Polycarbonate does not absorb sound as well as other facade materials. You may hear a drumming effect during storms.

If you install polycarbonate sheets in areas with frequent rain or hail, you should expect higher noise levels. You might find that the sound travels easily through polycarbonate, making indoor spaces less peaceful. Some building owners use acoustic insulation to reduce this problem. You should consider this extra step if you want a quieter environment.

Occupant Comfort

You want building occupants to feel comfortable at all times. Polycarbonate sheets can make this difficult in noisy weather. The sound of rain or hail on polycarbonate can interrupt meetings, classes, or daily activities.

- Polycarbonate facades often fail to block outside noise.

- Polycarbonate sheets may let in more sound than glass or masonry.

You should think about the location of your polycarbonate facade. If you use polycarbonate sheets near quiet zones, you risk disturbing people inside.You should always test the noise level before final installation. Polycarbonate offers many benefits, but you must weigh these against the impact on occupant comfort. Careful planning helps you avoid complaints and ensures a better experience for everyone.

Visual Confusion

Light and Shade Effects

You will notice that polycarbonate facades create unique light and shade patterns inside your building. Polycarbonate sheets allow natural light to pass through, but the effect can be unpredictable. Sometimes, polycarbonate sheets scatter light unevenly, which leads to glare or bright spots. You may find that these patterns shift throughout the day as the sun moves.

Polycarbonate can also cause color distortion. You might see colors inside your building appear different from their true shade. This effect can distract occupants or make spaces feel less comfortable. Polycarbonate sheets with textured surfaces may soften light, but they can also blur details. You should consider how these visual changes will impact your design goals.

Sensitive Environments

You must take extra care when using polycarbonate in sensitive environments. Polycarbonate sheets can create confusing visual effects in places like hospitals, schools, or offices. In these settings, clear visibility and consistent lighting are important for safety and comfort.

- Polycarbonate can cause reflections that distract or confuse people.

- Polycarbonate sheets may create shadows that hide hazards or obstacles.

You should avoid polycarbonate facades in areas where precise lighting is critical. Polycarbonate sheets may not suit spaces that require accurate color rendering, such as art studios or laboratories.

Polycarbonate offers many benefits, but you must weigh the risk of visual confusion. Careful planning helps you avoid problems that affect both appearance and function.

Cost of Polycarbonate Facades

Initial Expense

You will notice that polycarbonate facades often come with a higher upfront cost than traditional materials. The price per square foot can exceed that of basic glass or metal panels.

You must also budget for specialized fasteners and sealants.

These items add to your initial investment.You may need to purchase thicker sheets for better performance. Thicker panels increase the material cost.If you plan a large project, the total expense can rise quickly. Always request detailed quotes before you commit.

Value Assessment

You should look beyond the initial price when you assess value. Polycarbonate facades offer benefits like reduced structural load and faster installation.You may save money on support structures because polycarbonate weighs less than glass.

- Lower weight can reduce foundation costs.

- Faster installation may shorten your project timeline.

You must consider long-term maintenance. Polycarbonate can scratch or yellow, which may lead to replacement costs.You should compare the total cost of ownership with other materials. Factor in repairs, cleaning, and expected lifespan.A careful value assessment helps you decide if polycarbonate facades fit your project goals.

Lifespan and Replacement

Expected Service Life

You can expect polycarbonate facades to last between 10 and 20 years in most environments. Polycarbonate sheets resist many weather conditions, but their lifespan depends on exposure to sunlight, temperature swings, and physical impacts. You may notice that polycarbonate loses clarity or yellows as it ages. This change signals the need for replacement.

Polycarbonate sheets with UV protection last longer than basic panels. You should always check the manufacturer’s data for expected service life. In harsh climates, polycarbonate may show signs of wear sooner. You can extend the lifespan by choosing thicker polycarbonate sheets and installing them with care.

Maintenance Needs

You must plan for regular maintenance to protect the durability of polycarbonate facades. Polycarbonate sheets require gentle cleaning with mild soap and water. Harsh chemicals or abrasive tools can damage the surface and reduce durability. You should avoid using strong solvents on polycarbonate.

You may need to reseal joints or replace damaged polycarbonate sheets after storms or heavy impacts. Regular inspections help you spot cracks, leaks, or yellowing before they become serious problems. Polycarbonate facades need more attention than glass or metal to maintain their appearance and durability.

- Clean polycarbonate sheets with soft cloths.

- Check for scratches or dents after severe weather.

- Replace polycarbonate sheets that lose clarity or show deep damage.

You should keep a maintenance schedule for your polycarbonate facade. This habit helps you avoid unexpected repairs and keeps your building looking modern.

Environmental Concerns

Recycling Issues

You may think polycarbonate offers strong resistance to weather and impact, but recycling this material presents real challenges. Most recycling centers do not accept polycarbonate because it requires special processing.You will find that polycarbonate has a complex chemical structure. This structure gives it high resistance to heat and UV, but it also makes recycling more difficult.

You should know that mixed plastics, including polycarbonate, can contaminate recycling streams. This contamination lowers the resistance of recycled products and reduces their quality.

If you want to recycle polycarbonate, you must locate specialized facilities.

These facilities use advanced methods to maintain the resistance of the material during processing.

You may face higher costs and longer transport times when you choose to recycle polycarbonate. Many projects skip recycling because of these barriers.

Disposal Challenges

You will encounter more issues when disposing of polycarbonate facades. The material’s resistance to decay means it can last for decades in landfills. Polycarbonate does not break down easily. This resistance to decomposition creates long-term environmental concerns. You should avoid burning polycarbonate. High resistance to heat does not prevent the release of toxic gases during incineration.

Some disposal methods can damage the environment or harm public health. You must plan for responsible disposal to reduce negative impacts.You can reduce waste by reusing polycarbonate sheets in other projects. This approach takes advantage of the material’s resistance and extends its useful life.

Conclusion

You face several disadvantages when you choose polycarbonate facades. Scratching, UV degradation, and impact damage can threaten safety and performance. You must consider fire safety and chemical sensitivity before installation. Water intrusion and joint weakness also affect safety in your building. Always consult experts to ensure safety standards match your project. You protect safety by evaluating every risk and selecting the right material for your needs.