Selecting the right skylight material is key for balancing aesthetics, performance, and longevity.

Polycarbonate and acrylic are popular choices, each with distinct advantages in weight, flexibility, light transmission, durability, UV resistance, and insulation.

This comparison highlights the main differences between polycarbonate and acrylic skylights, helping readers choose the best material for their climate, budget, and lighting needs.

How Acrylic and Polycarbonate Panels Are Made

Acrylic and polycarbonate sheets are widely used in construction, signage, and design due to their strength, transparency, and versatility. Understanding their manufacturing processes helps ensure the right material is chosen for each application.

Acrylic Sheets

Acrylic sheets are produced through bulk polymerization, where the liquid monomer, methyl methacrylate, reacts with a catalyst in sealed molds. Thin sheets cure in hours, while thicker sheets may take several days to harden. Once cooled, the sheets can be used as-is or further processed to improve clarity and surface quality. Two main methods exist: batch cell casting, which is suitable for thicker, wide sheets with high optical quality, and continuous casting, which is faster and used for thinner sheets. Acrylic offers excellent clarity and rigidity, making it ideal for applications requiring precision and smooth surfaces.

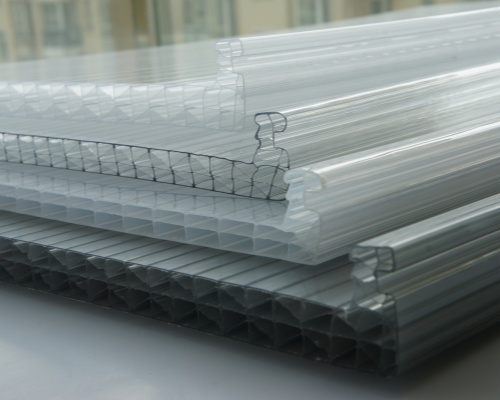

Polycarbonate Sheets

Polycarbonate sheets are primarily manufactured via extrusion. Pellets of raw polycarbonate are melted in an extruder and forced through a die to form flat sheets of consistent thickness. During extrusion, sheets can be customized with colors, textures, gloss finishes, or multiple layers. After extrusion, additional finishing processes may be applied for specific thicknesses, surface quality, or layered construction. Polycarbonate is highly impact-resistant and flexible, making it suitable for roofing, glazing, and protective panels.

Comparing Polycarbonate and Acrylic Skylights

Weight and Flexibility

Polycarbonate Skylights

Polycarbonate skylights use a tough plastic material. Polycarbonate offers high impact resistance, making it ideal for areas with hail or falling debris. These skylights resist cracking and breaking much better than glass or other plastics.

Polycarbonate skylights also provide strong UV protection. Manufacturers often add special coatings to block harmful ultraviolet rays. This helps protect furniture and flooring from fading.

Acrylic Skylights

Acrylic skylights stand out for their optical clarity. Acrylic allows more visible light to pass through, creating bright and clear interiors. Many people choose acrylic skylights for spaces where natural light quality matters.

Acrylic resists scratches better than polycarbonate. This helps maintain a clear view over time. Acrylic skylights also offer good thermal insulation, which can help control indoor temperatures.

Comparison Table

|

Property |

Polycarbonate Skylights |

Acrylic Skylights |

|---|---|---|

| Weight | Lighter | Slightly heavier |

| Flexibility | Very flexible | More rigid |

Polycarbonate skylights weigh less than acrylic skylights. Polycarbonate can bend without breaking, which allows for creative skylight shapes. Acrylic skylights remain more rigid and may crack under stress.

Light Transmission & Clarity

Natural light

While polycarbonate skylight panels allow plenty of natural light, acrylic skylights often let in even more, making them the preferred choice for builders seeking the brightest interiors.

Acrylic skylights can transmit up to 92% of visible light. Polycarbonate usually transmits slightly less, around 88%. This difference can affect how bright a room feels during the day.

Optical clarity differences

Acrylic skylights provide excellent optical clarity. The material looks almost as clear as glass. Many people cannot tell the difference between acrylic and glass from a distance.

Polycarbonate skylights have good clarity but may appear less transparent than acrylic. Over time, polycarbonate can develop a slight haze. Acrylic keeps its clear look for many years with proper care.

Durability

Polycarbonate Skylights

Polycarbonate skylights show impressive durability in many environments. They resist impacts from hail, debris, and even accidental falls. This material does not crack easily, which helps maintain the skylight’s structure over time.

Many builders choose polycarbonate skylights for areas with harsh weather. The panels withstand heavy rain, snow, and strong winds. Their longevity makes them a reliable choice for both homes and commercial buildings.

Polycarbonate skylights also resist chemical damage. They do not react with most cleaning agents or pollutants. This resistance adds to their overall longevity and reduces maintenance needs.

Acrylic Skylights

Acrylic skylights offer good durability, but they do not match polycarbonate in impact resistance. Acrylic can crack if struck by large hail or heavy objects. However, it resists scratches better than polycarbonate.

Acrylic skylights perform well in mild climates. They handle sunlight and rain without losing clarity. Their longevity depends on the environment and how much physical stress they face.

Acrylic skylights may show signs of wear after many years. Small cracks or cloudiness can appear if exposed to repeated impacts. Regular cleaning and gentle handling help extend their longevity.

|

Durability Factor |

Polycarbonate Skylights |

Acrylic Skylights |

|---|---|---|

| Impact Resistance | Excellent | Moderate |

| Scratch Resistance | Moderate | Excellent |

| Weather Resistance | High | Good |

| Longevity | Long | Moderate |

UV Resistance

Polycarbonate Skylights

Polycarbonate skylights offer strong protection against ultraviolet (UV) rays. Manufacturers often add UV-blocking coatings to the surface. These coatings help prevent harmful rays from entering indoor spaces.

Polycarbonate blocks almost all UV radiation. This feature protects people, furniture, and flooring from sun damage. Over time, the skylight keeps its strength and clarity because of this UV resistance.

A polycarbonate skylight also helps reduce the risk of skin damage from UV exposure. Many schools, offices, and homes use polycarbonate for this reason. The material keeps interiors safe and comfortable.

Acrylic Skylights

Acrylic skylights also provide some UV protection. The material naturally filters out a portion of UV rays. Some acrylic skylights include extra UV-resistant additives for better performance.

Acrylic does not block as much UV radiation as polycarbonate. Over time, exposure to strong sunlight can cause acrylic to yellow or lose clarity. Regular cleaning and maintenance help slow this process.

|

Feature |

Polycarbonate Skylights |

Acrylic Skylights |

|---|---|---|

| UV Blocking Ability | Excellent | Good |

| Yellowing Resistance | High | Moderate |

| Long-Term Clarity | Maintains clarity | May fade |

Insulation & Energy Efficiency

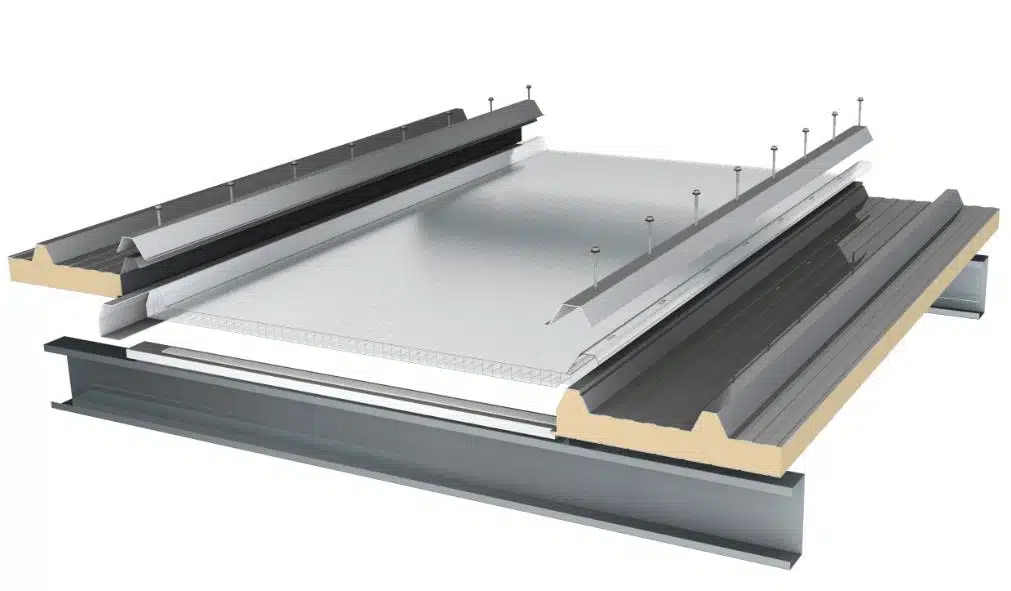

Polycarbonate Skylights

Polycarbonate skylights provide strong thermal performance. The material traps air between layers, which helps reduce heat transfer. Many polycarbonate skylight domes use multi-wall designs to improve insulation.

These skylights show excellent insulation properties. Builders often choose them for projects that require energy efficiency. Polycarbonate skylights help keep indoor temperatures stable during hot summers and cold winters.

The durable construction of polycarbonate skylights also supports long-term performance, resulting in lower heating and cooling costs due to their thermal efficiency. Polycarbonate skylights maintain their performance even after years of use.

Acrylic Skylights

Acrylic skylights offer good thermal performance, but they do not match polycarbonate in insulation. Single-layer acrylic panels allow more heat to pass through. Some acrylic skylights use thicker panels to improve performance.

Acrylic skylights still contribute to energy efficiency in mild climates. They help reduce drafts and keep rooms comfortable. However, their thermal performance may not be enough for areas with harsh winters or hot summers.

Acrylic skylights perform best in spaces where light quality matters more than insulation. Their clear panels allow sunlight to enter while providing some protection from outdoor temperatures.

|

Feature |

Polycarbonate Skylights |

Acrylic Skylights |

|---|---|---|

| Thermal Performance | Excellent | Good |

| Energy Efficiency | High | Moderate |

| Insulation Properties | Excellent | Moderate |

Clarity & Light Transmission

Clarity and bright light transmission matter for many spaces. Acrylic glazing offers the highest clarity among skylight materials. It allows more visible light to pass through, making rooms feel open and bright.

Polycarbonate glazing provides good light transmission but usually appears less clear than acrylic. Over time, polycarbonate may develop a slight haze, while acrylic glazing keeps its transparency longer.

For spaces where clear views and natural daylight are priorities, acrylic glazing often wins in this skylight comparison.

Impact Resistance

Impact resistance is a key factor in any skylight comparison. Polycarbonate glazing stands out for its high impact resistance. It can handle hail, falling branches, and other debris without cracking.

Acrylic glazing offers moderate impact resistance but does not match polycarbonate. In areas with frequent storms or risk of damage, polycarbonate glazing is the more impact resistant choice.

Polycarbonate vs acrylic often comes down to this difference in high impact resistance.

Weight

Weight affects installation and design flexibility. Polycarbonate glazing is lighter than acrylic glazing. This makes it easier to handle and install, especially for large skylights.

Acrylic glazing weighs slightly more and feels more rigid. Polycarbonate’s flexibility allows for creative skylight shapes and curved designs.

When comparing polycarbonate vs acrylic, weight and flexibility can influence the final choice of skylight materials.

|

Feature |

Polycarbonate Glazing |

Acrylic Glazing |

|---|---|---|

| Clarity | Good | Excellent |

| Bright Light Transmission | High | Very High |

| Impact Resistance | Excellent | Moderate |

| Weight | Light | Slightly heavier |

| Flexibility | High | Low |

Applications

Polycarbonate Skylights

Polycarbonate skylights work well in places that need strong impact resistance. Schools, factories, and sports centers often use these skylights to protect against hail or falling debris.

Builders also choose polycarbonate for greenhouses because the material lets in light while keeping plants safe.

Many architects use polycarbonate skylights in public buildings. These skylights handle heavy foot traffic and rough weather. Polycarbonate panels also fit curved or creative roof designs because of their flexibility.

Acrylic Skylights Uses

Acrylic skylights suit spaces where clear, bright light is important. They are often installed in kitchens, bathrooms, and living rooms to create a welcoming atmosphere.

Artists and designers prefer acrylic skylights for studios because the material provides true color and crisp daylight.

Museums and galleries use acrylic skylights to highlight artwork with natural light. Acrylic skylight domes appear in shopping centers and atriums, where they add style and allow sunlight to fill large spaces.

Many residential projects use acrylic skylights for their easy installation and attractive appearance.

- Polycarbonate skylights offer superior uv stability and high resilience against impacts.

- Acrylic skylights provide excellent clarity and bright light for indoor spaces.

- One should consider climate, budget, and lighting needs before choosing a skylight material.

Conclusion

Choosing between polycarbonate and acrylic skylights depends on performance and priorities.

Polycarbonate offers superior impact resistance, flexibility, UV protection, and insulation, making it ideal for harsh climates.

Acrylic provides excellent clarity and stiffness, enhancing interior lighting and aesthetics. Consider climate, budget, and lighting needs to select the skylight that best balances durability, appearance, and functionality.