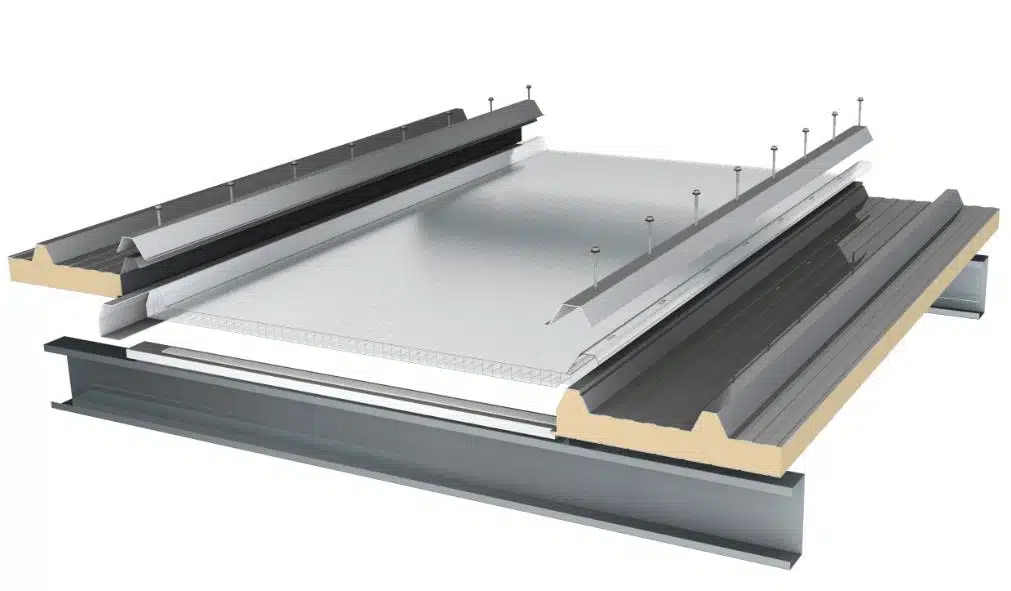

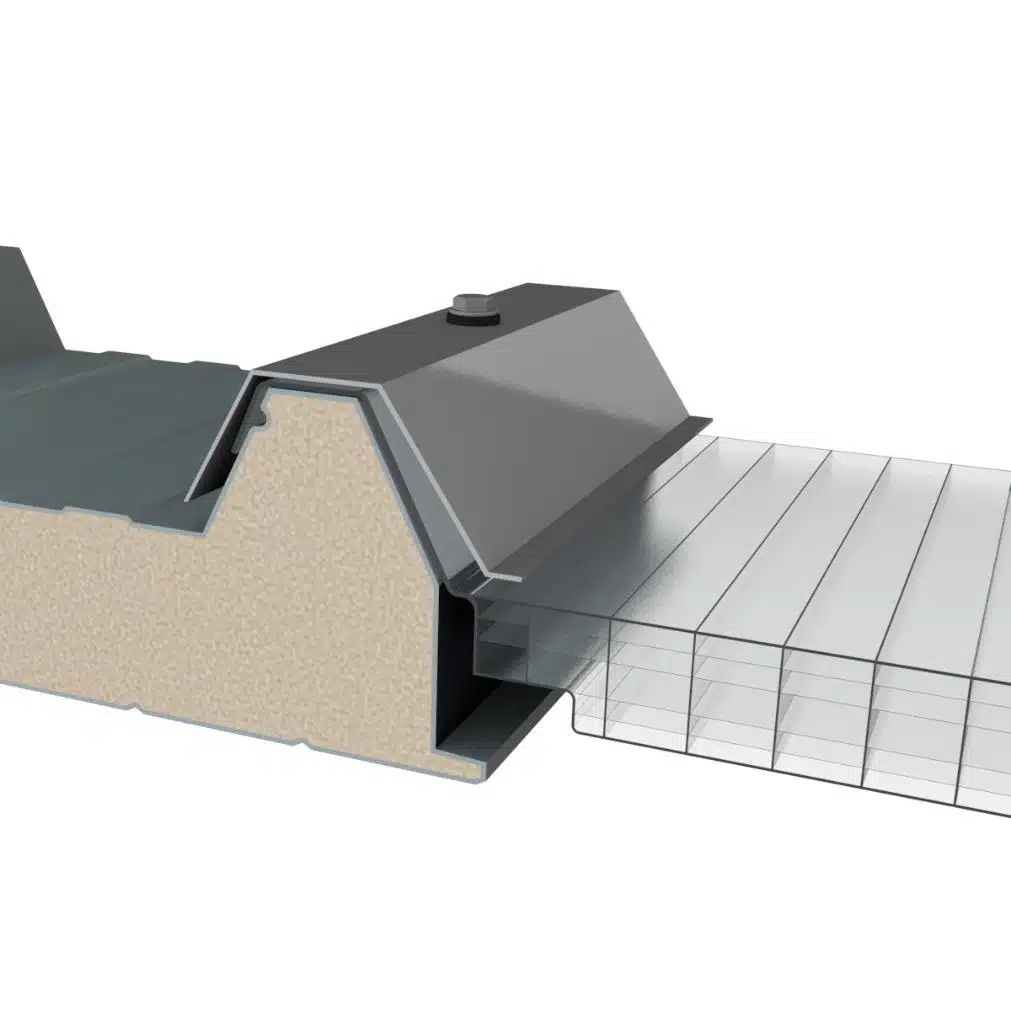

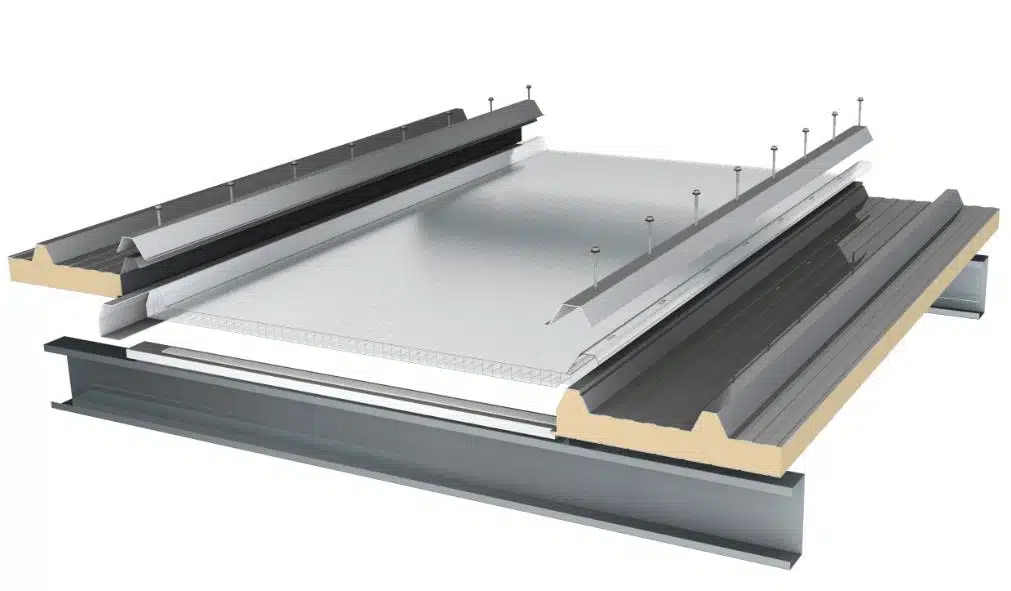

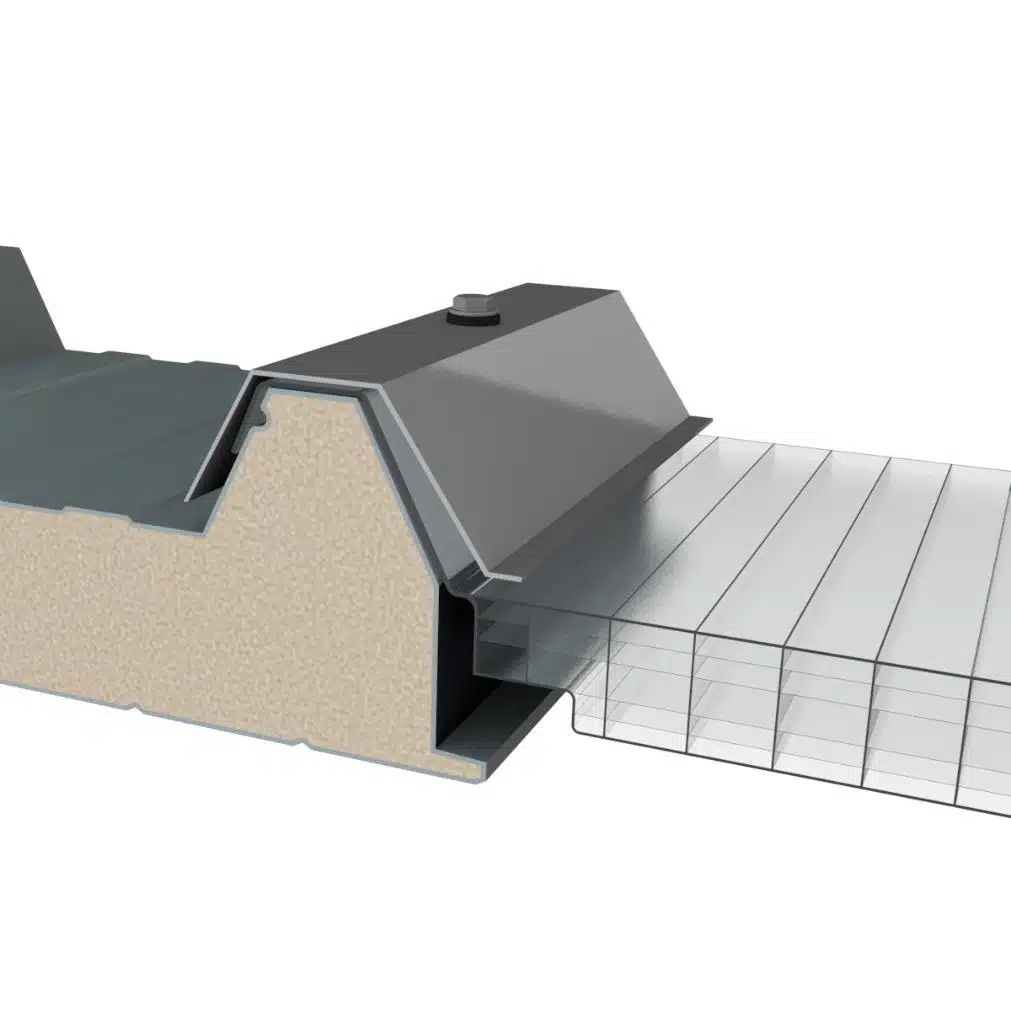

Polycarbonate skylight panels is a revolutionary Polycarbonate Architecture System in modern building design, the panels can be integrated into roof constructions made of trapezoidal sheet metal or profiled sandwich panels in an economical, quick, and easy manner. Due to their flexible sizes and versatile applications, these panels allow for a high degree of design freedom.

Key Features of Polycarbonate Skylight Panels

- Aesthetic Appeal: Insulate buildings while allowing natural daylight, energy efficient wall solutions.

- Fire-rated Curtain Wall Materials: UL94 flame resistant – V0, V2

- Easy Installation and Maintenance: Polycarbonate material is lighter than traditional panels, making them easy to installation.

- Durability: UV-stable polycarbonate sheets, 15 years warranty for yellowing

- Design Flexibility: Customize polycarbonate panels colors, and aluminum frame structures

- Variety of Options: High-performance glazing solutions, Facaplex offers different types of polycarbonate panels with different transparencies and tints.

- System Benefits: Each component in the system can expand and contract at its own rate, it eliminates waves and deformation while maintaining the structural properties of the materials.

Specifications of Polycarbonate Sheets

| Material | Polycarbonate Roof Panels |

|---|---|

| Thickness | 30mm +/- 0.5mm |

| Width | 1005 / 924mm |

| Weight | approx. 3.5 kg/sqm |

| Fire Resistance | UL94 V0, V2 |

| Temperature Adaptability | Long-term operating temperature: -40°C to +120°C. |

| Light Transmission | Light opal approx 45%; Clear approx 70% |

| Impact Resistant | The impact strength is 250 times of glass and 30 times that of acrylic. |

| Weather Resistant | Co-extruded UV-resistant coating, ensuring excellent outdoor weather resistance. |

Skylight Applications of Polycarbonate Panels

- Commercial Buildings, large expanses of glass-like material that enhance visibility, light penetration, and modern aesthetics

- Hotels

- Public Safety Glazing

- Polycarbonate partition walls

Services Offered

Facaplex provides fabrication and thermoforming services for polycarbonate solid sheets, complemented by top-tier silkscreen printing. Our skilled team can create tailored shapes and designs, improving both the aesthetic and functional aspects of polycarbonate products for a wide range of applications.

1. Vacuum thermoforming for polycarbonate sheets

DBI showcase the iconic columns on the main entry of W Brisbane, with a reflective ceiling and illumination to create a unique effect.

But polycarbonate materials convey the concept of a lightweight and light-transmitting design concept, they also retain the metallic texture of aluminum panels.

2. Silkscreen printing and digital printing on polycarbonate sheets

Allows for personalized graphics, logos, and text tailored to specific preferences. Offers efficient printing for both small and large projects.

Louis Vuitton Maison Osaka Midosuji utilizes washi paper and glass curtain walls in its design. However, polycarbonate (PC) can achieve a similar effect when silk screen printing techniques, providing a lightweight and versatile alternative that captures the aesthetic qualities of traditional materials.

Why Choose Facaplex?

- Expertise in Manufacturing

As a leading polycarbonate manufacturing and fabrication factory, we specialize in products and processing manufacture.

We’re a group company specialized in construction field, we can produce a wide range of aluminum products tailored to your specific plastic sheets need. - Design Capability

Our team of experienced professionals is committed to transforming your ideas into innovative solutions. We work closely with clients to deliver customized designs that align with their vision and functional requirements. - Quality Assurance

We prioritize quality at every stage of production, from sourcing raw materials to final inspection, ensuring that our products exceed industry standards. - Competitive Pricing

Our efficient manufacturing processes and direct sourcing of materials enable us to offer competitive pricing without compromising on quality. - Short Delivery Time

- Comprehensive Support

From initial consultation to modular facade design, post-production transportation support, we provide comprehensive assistance throughout the entire project.

FAQ

Polycarbonate is a thermoplastic polymer recognized for its high impact resistance. It quickly gained popularity as safety glass and has been extensively used in curtain walls and facades. Its strength and versatility have seamlessly transitioned into architecture, where its translucency is ideal for various daylighting solutions, including curtain walling and wall light panels.

Our curtain wall installation services focus on a unitized system that enhances efficiency and quality. Pre-assembled panels are meticulously fabricated in our factory, ensuring precision and reducing on-site installation time. This approach not only streamlines the installation process but also minimizes potential errors, resulting in a seamless and aesthetically pleasing facade.

Yes, curtain walls are considered safe when they are properly designed, installed and maintained. Many curtain wall systems use impact-resistant materials, such as tempered glass or polycarbonate, to enhance safety, especially in areas prone to extreme weather or vandalism.

A unitized curtain wall is a type of building facade system consisting of pre-assembled panels that are fabricated in a factory and then transported to the construction site for installation.

Curtain Wall

A curtain wall is a non-structural outer covering of a building that is designed to resist air and water infiltration, as well as provide structural support to the building facade.

Material: Typically made from materials like glass, polycarbonate, aluminum, and structural framing systems.

Functionality: Curtain walls are primarily used to enclose a building and provide views and natural light while maintaining energy efficiency. They are designed to handle wind loads and other environmental factors.

Attachment: Attached to the building’s structural frame but do not bear any of the building’s weight. Instead, they are supported by the main structure.

Cladding

Cladding refers to the application of one material over another to provide a skin or layer that offers protection and aesthetic appeal.

Material: Can be made from a wide range of materials, including polycarbonate, wood, metal, vinyl, brick, stone, and composite materials.

Functionality: Primarily serves to protect the building from weather elements, enhance aesthetics, and improve insulation. Cladding is also important for moisture management.

Benefits of Corrugated Design For Polycarbonate Skylight Panels

Corrugated polycarbonate panels stand out primarily due to their corrugated structure, which refers to the wave-like ridges that run along the surface. This design is a key feature because it adds significant strength and rigidity to the panel while keeping it lightweight. The corrugation creates air pockets between the peaks and valleys, which enhances insulation properties. This helps to reduce heat loss and maintain a stable indoor temperature.

The corrugated shape also increases the panel’s resistance to external pressures like wind, hail, and heavy rain. The rigidity provided by the grooves makes the panels more durable and capable of withstanding impacts better than flat sheets. Additionally, the design facilitates the flow of rainwater, reducing the chances of water pooling on the roof.

For skylights, these panels offer several advantages:

Structural Strength: The corrugation improves the panel’s ability to withstand pressure, making it ideal for areas with harsh weather conditions.

Light Diffusion: The shape of the corrugated panels helps diffuse light evenly throughout the space, reducing glare while maximizing natural daylight.

Easy Installation: The design allows for simpler and faster installation, as the panels can easily overlap and lock into place.

In short, the corrugated feature of these polycarbonate panels plays a crucial role in enhancing their durability, insulation, and ease of installation, making them a top choice for skylights.

Get Free Quote of Polycarbonate Skylight Panels

Looking for durable and energy-efficient polycarbonate skylight panels? Get a free quote today! Our high-quality panels offer excellent strength, insulation, and light diffusion for your skylight projects. Perfect for residential, commercial, and industrial use. Contact us now to receive a personalized quote and discover how our panels can enhance your space!

Related Products

Related News

Twinwall polycarbonate roofs are a versatile and durable solution for both residential and commercial projects. Known for their lightweight yet […]

Multi-Wall Polycarbonate is a versatile building material known for its unique combination of strength, light weight, and thermal efficiency. Unlike […]

Choosing the right roofing material can make a huge difference in both the durability and appearance of your outdoor or […]

Understanding Twinwall Polycarbonate Roof Features Polycarbonate pergola roof stands out for its lightweight yet strong structure. This material resists impacts […]

The main difference between twin wall polycarbonate and multiwall polycarbonate lies in the number of layers. Twin-wall polycarbonate features two […]

The difference between solid and multiwall polycarbonate sheets lies in their structure and performance. Solid polycarbonate looks like glass and […]

Selecting the right thickness for polycarbonate panels greatly impacts performance and longevity. People often compare polycarbonate versus glass, but polycarbonate […]

When choosing custom polycarbonate panels, buyers often look beyond basic durability. Key factors such as available sizes, cut-to-size options, thickness […]