Translucent Polycarbonate Ceiling Cost is a key consideration for architects, builders, and project managers seeking durable, light-enhancing solutions in 2025.

Widely used in commercial and industrial construction, these ceiling systems offer excellent thermal insulation, impact resistance, and natural light diffusion.

This guide outlines current cost per square foot, key pricing factors, and what to expect when specifying polycarbonate ceilings for large-scale projects.

2025 Cost Overview

Average Price per Square Foot

Translucent polycarbonate ceiling panels cost between $1.35 and $2.04 per square foot in 2025. Labor charges add $2 to $5 per square foot. The total installed price usually falls between $5 and $28 per square foot.

Most projects with translucent polycarbonate ceiling panels land on the higher end of this range.

Price Ranges

Prices vary based on panel thickness and type. Thicker panels and advanced structures increase the cost per square foot. The table below shows how quantity affects the price per sheet and the approximate cost per square foot:

| Quantity Range | Price per Sheet (Example Size) | Approximate Price per Square Foot |

| 1 – 2 | $73.46 | Higher cost per sq ft |

| 3 – 9 | $70.48 | Slightly reduced cost |

| 10 – 19 | $63.35 | Noticeable reduction |

| 20 – 29 | $58.59 | Further reduction |

| 30 – 49 | $55.61 | Lower cost |

| 50+ | $52.64 | Lowest cost per sq ft |

Translucent Polycarbonate Ceiling Cost Factors

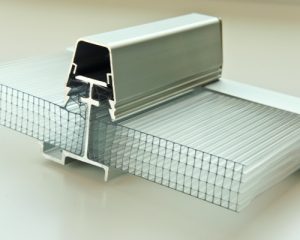

Material Quality

Material quality plays a major role in the final price of a translucent polycarbonate ceiling. Higher-grade panels, such as those with flame retardant or UV-resistant features, cost more because they last longer and perform better.

These panels often range from $2 to $10 per square foot. Buyers pay more for better durability, strength, and resistance to weather or chemicals. Choosing high-quality materials increases the initial cost but can reduce repairs and replacements over time.

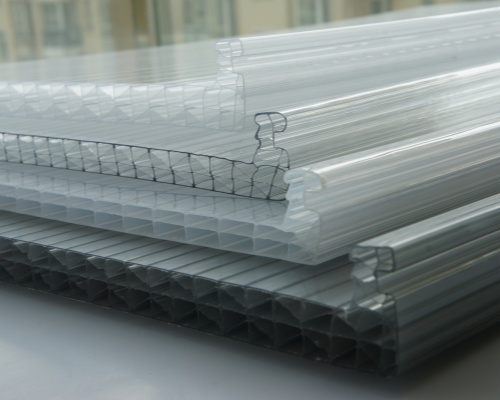

Thickness

Panel thickness affects both the price and performance of a translucent polycarbonate ceiling. Thicker panels withstand more pressure from wind, hail, or snow.

They also allow for wider spacing between supports, which can lower framing costs. The table below shows how thickness influences different aspects of a project:

| Factor | Description |

| Panel Thickness Options | 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm |

| Structural Performance | Thicker panels handle higher loads |

| Framing Requirements | Thicker panels need less support |

| Cost Difference | 2.0mm panels cost 3-4 times more than 0.8mm panels |

| Long-term Benefits | Thicker panels last longer and save energy |

| Code Compliance | Thicker panels meet stricter building codes |

Common thicknesses range from very thin sheets to panels up to 4 inches. Multiwall and solid panels offer different benefits for insulation and strength.

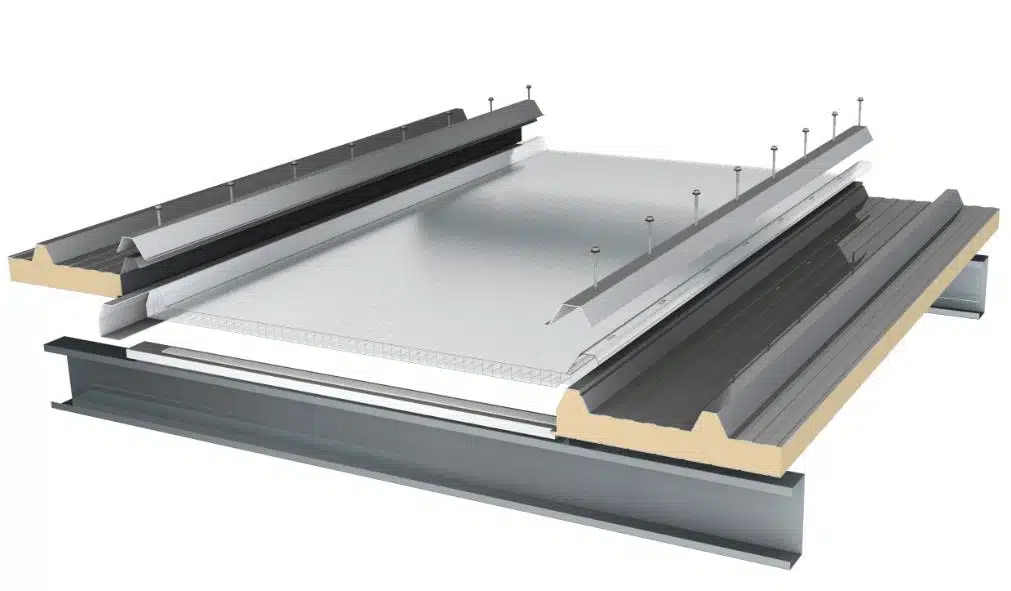

Installation Complexity

Installation complexity can raise or lower labor costs. Polycarbonate panels weigh less than glass, making them easier and faster to install. Their flexibility allows for easy cutting and shaping, which helps with complex designs.

However, installers must manage thermal expansion and use proper sealing to prevent leaks or warping. Mistakes during installation, such as poor alignment or sealing, can lead to higher repair costs.

Regular maintenance also helps avoid expensive replacements.

Location

Location impacts the cost of a translucent polycarbonate ceiling due to regional price differences and local building codes. Areas with high demand or strict safety standards may see higher prices.

Raw material costs, supply chain issues, and local labor rates also affect the final price. In 2025, supply chain disruptions and increased demand in construction can cause prices to fluctuate.

Technological advances and regional incentives for green building may help stabilize or lower costs in some markets.

Material Comparisons

Glass Ceilings

Glass ceilings offer a premium look and excellent clarity. They let in a lot of natural light and can make spaces feel larger.

- Glass is available in many colors and stays clear over time.

- It is heavy, brittle, and can break easily.

- Glass absorbs heat, which can make rooms warmer in hot climates.

- Installation requires specialists and can be dangerous if the glass shatters.

- Glass costs more than most other ceiling materials and has poor insulation.

Translucent Polycarbonate Ceiling panels provide similar clarity but are lighter and much more durable. They resist impacts and offer better insulation and energy efficiency.

Acrylic Ceilings

Acrylic ceilings cost less than both glass and polycarbonate options. They have a shiny, high-gloss finish and are easy to machine and polish.

| Feature | Acrylic Ceilings | Translucent Polycarbonate Ceiling |

| Cost | $0.9–$1.0/sq ft | Higher per sq ft |

| Appearance | Shinier, more transparent | Modern, more translucent |

| Impact Resistance | Prone to cracking | Highly impact-resistant |

| Weight | Heavier | Lighter |

| Heat Resistance | Lower | Higher |

| Scratch Resistance | More durable | Scratches easily |

Acrylic panels are more brittle and less heat-resistant than polycarbonate. Polycarbonate panels last longer and handle impacts better, but cost more.

Traditional Ceilings

Traditional ceilings use materials like drywall, plaster, or tiles. These options cost less than glass or polycarbonate.

- Traditional ceilings do not allow natural light through.

- They offer good sound insulation and are easy to repair.

- These ceilings lack the modern look and energy-saving benefits of translucent panels.

- Installation is simple, but they do not improve lighting or ambiance.

Translucent Polycarbonate Ceiling panels help reduce lighting costs and create a brighter, more open space. They also install faster than most traditional materials.

Project Examples

Sample Costs

Translucent polycarbonate ceiling projects in 2025 show a wide range of costs. A small residential sunroom with basic panels may cost around $2,500 for materials and labor.

Larger commercial spaces, such as office atriums, often see total costs between $15,000 and $40,000. The final price depends on panel thickness, framing, and installation complexity.

Bulk orders lower the price per square foot, making large projects more affordable. Specialty panels and advanced framing systems increase the total cost but provide better performance.

Case Studies: Translucent Polycarbonate Ceiling Benefits

Recent case studies highlight the long-term value of polycarbonate ceiling systems in commercial and industrial settings. Retrofitting older buildings with these panels extends exterior lifespan and minimizes ongoing maintenance.

Their superior thermal insulation compared to glass helps reduce heating and cooling costs, improving overall energy efficiency.

Although installation may involve enhanced framing and specialized gaskets to manage thermal movement and water drainage, the long-term benefits—lower energy use and extended durability—make polycarbonate ceilings a smart investment for large-scale projects.

Conclusion

Translucent polycarbonate ceilings offer a cost-effective, durable, and light-enhancing solution for modern commercial and industrial environments.

Understanding the 2025 cost per square foot helps B2B buyers make informed decisions, optimize project budgets, and select the right materials for long-term value and performance.

Facaplex offers high-quality polycarbonate systems that ensure excellent durability and energy efficiency.