Twinwall polycarbonate roofs are a versatile and durable solution for both residential and commercial projects. Known for their lightweight yet strong construction, these multi-layered panels provide excellent thermal insulation, high light transmission, and long-lasting protection against UV rays and weather elements. This guide explores the key benefits of twinwall polycarbonate roofs, outlines practical installation tips, and provides essential maintenance advice to ensure optimal performance and longevity.

What Are Twinwall Polycarbonate Roofs

Structure and Material

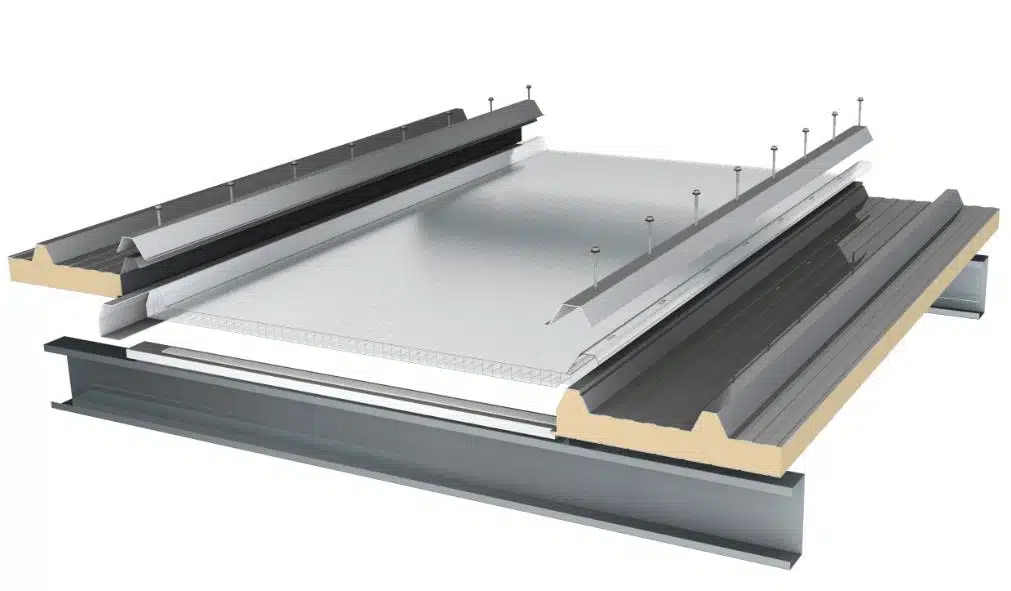

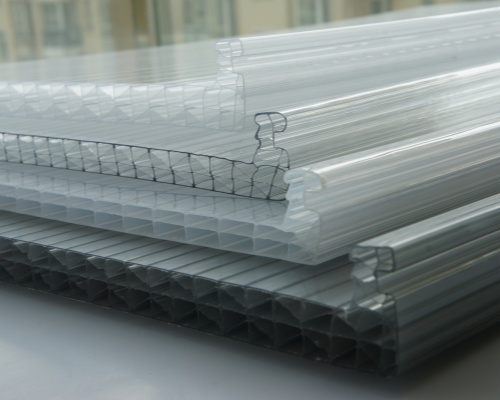

Twinwall polycarbonate roofs use two layers of polycarbonate separated by a hollow space. This structure creates air pockets that improve insulation and strength. The panels feel lightweight but resist impacts and harsh weather.

Manufacturers produce polycarbonate roofing sheets in various thicknesses and sizes. These sheets often include UV protection on one side to prevent yellowing and damage. The panels can be cut to fit different roof shapes and designs.

Polycarbonate offers high clarity and durability. The material does not shatter like glass. Many builders choose polycarbonate roofing sheets for their long lifespan and low maintenance needs.

Common Uses

Twinwall polycarbonate roofs appear in many building projects. These panels are used for greenhouses, patio covers, and carports. The panels allow natural light to enter while blocking harmful UV rays.

Schools and commercial spaces often select polycarbonate roofing sheets for covered walkways and skylights. The panels provide a safe and bright environment. Builders also use polycarbonate for pergolas and sunrooms.

Polycarbonate roofing sheets work well in both residential and commercial settings. The panels offer flexibility for curved or flat roof designs. Many people prefer these panels for their easy installation and energy-saving properties.

Benefits of Twinwall Polycarbonate Roofs

Durability

Twinwall polycarbonate roofs offer strong resistance to impacts and harsh weather. The double-layer design helps the panels withstand hail, wind, and heavy rain. Polycarbonate roofing sheets do not crack or shatter easily, making them a safe choice for many projects.

Many builders choose polycarbonate for its long lifespan. The material resists fading and yellowing when installed with the UV-protected side facing out. Twinwall polycarbonate roofs keep their strength and clarity over time.

Insulation

Twinwall polycarbonate roofs provide excellent insulation. The air gap between the layers reduces heat loss in winter and limits heat gain in summer. Polycarbonate roofing sheets help maintain a comfortable temperature inside greenhouses, patios, and sunrooms.

A table below shows how insulation compares:

| Material | Insulation Value (R-value) |

|---|---|

| Twinwall Polycarbonate | High |

| Single-layer Polycarbonate | Medium |

| Glass | Low |

Polycarbonate panels help lower energy costs by reducing the need for heating and cooling. Many people notice a difference in comfort after installing polycarbonate roofing sheets.

Light Transmission

Twinwall polycarbonate roofs allow natural light to pass through while blocking harmful UV rays. The panels create bright spaces without glare. Polycarbonate diffuses sunlight, which helps protect plants and furniture from sun damage.

- Twinwall panels offer different levels of light transmission.

- Clear panels let in the most light, while tinted options provide shade.

- Polycarbonate roofing sheets give flexibility for many lighting needs.

Twinwall polycarbonate roofs work well for spaces that need both light and protection.

Install Twinwall Polycarbonate Roofs

Tools and Materials

Installers need essential tools and materials for a successful installation. The most common tools include a circular saw with a fine-tooth blade, a drill, and a measuring tape. Workers also use foam glazing tape, gaskets, and screws designed for polycarbonate roofing sheets.

A table below lists essential tools and materials:

| Tools | Purpose |

|---|---|

| Circular Saw | Cutting the sheets |

| Drill | Pre-tapping holes |

| Measuring Tape | Positioning the sheets |

| Foam Glazing Tape | Sealing and insulation |

| Gaskets | Sealing panel joints |

| Screws | Fixing the sheets |

Installers should wear gloves and safety glasses. These tools help achieve correct installation and protect the panels from damage.

Preparation

Preparation is key for installing multi-wall polycarbonate panels. Workers must inspect the panels for defects before installation. They should clean the work area and gather all essential tools and materials.

Pre-installation tips include storing panels flat and away from direct sunlight. Installers should measure the roof frame and mark the positions for fixing the sheets. Safety checks help prevent accidents during installation.

Installers must confirm the UV-protected side of the panels faces outward. This step ensures the panels resist yellowing and damage.

Step-by-Step Installation Process

The step-by-step installation process helps achieve correct installation and long-lasting results. Installers begin by cutting the sheets to fit the roof frame. They use a circular saw for cutting the sheets and wear safety gear.

Next, installers position the sheets on the frame. They place the panels with the UV-protected side facing up. Fasteners should be perpendicular to the panels and not too close to the edge.

Workers pre-tap holes in the panels to prevent cracking. They fix the sheets using screws and avoid over-tightening. Foam glazing tape goes between the panels and the frame for insulation and sealing.

Installers overlap the panels to prevent leaks. They use gaskets at joints for extra sealing. Safety remains important throughout the installation steps.

Sealing and Finishing

Sealing is essential for a successful installation. Installers apply foam glazing tape and gaskets to all joints and edges. These materials prevent water from entering between the panels.

Workers check each panel for gaps and secure all fasteners. They inspect the roof for proper sealing and finish by cleaning the surface. Safety checks ensure the panels are mounted correctly and securely.

Polycarbonate roofing sheets require careful sealing for long-term performance. Correct installation protects the panels from leaks and weather damage.

Maintenance and Troubleshooting

Cleaning

Regular cleaning helps maintain the clarity and performance of polycarbonate panels. Use a soft cloth or sponge with mild soap and water to remove dirt and debris. Avoid harsh chemicals, as they can damage the panels and reduce their lifespan.

A gentle cleaning routine keeps panels looking new and ensures proper light transmission. Panels should be cleaned twice a year for best results. Always check the manufacturer’s guidelines before starting the cleaning process.

Inspecting for Damage

Inspect polycarbonate panels for cracks, chips, or discoloration. Look for signs of wear after storms or extreme weather. Early detection helps prevent bigger problems and extends the life of the panels.

Create a checklist for inspections:

- Examine all panels for visible damage.

- Check the seals and joints for leaks.

- Confirm that installation fasteners remain secure.

If you find damage, replace the affected panels quickly. Proper installation and regular inspections help avoid costly repairs.

Common Issues

Some common issues with polycarbonate panels include leaks, condensation, and discoloration. Leaks often result from poor installation or damaged seals. Condensation can form inside panels if ventilation is inadequate.

A table below shows solutions for frequent problems:

| Issue | Solution |

|---|---|

| Leaks | Reseal joints, check installation |

| Condensation | Improve ventilation |

| Discoloration | Replace panels, check UV protection |

Proper installation and routine maintenance prevent most problems. Always follow best practices when handling polycarbonate panels.

Twinwall polycarbonate roofs offer strong durability, excellent insulation, and bright natural light. The panels are easy to install and simple to maintain.

Conclusion

Twinwall polycarbonate roofs offer a unique combination of durability, thermal efficiency, and aesthetic appeal. Their lightweight yet strong construction makes installation straightforward, while proper maintenance ensures long-lasting performance. From residential patios and greenhouses to commercial and industrial structures, these roofs provide reliable protection, energy savings, and modern design flexibility. Choosing the right panels and following installation and maintenance best practices will maximize both comfort and longevity, making twinwall polycarbonate roofs a smart investment for any project.