Polycarbonate panels have become one of the most popular materials in modern construction, especially for roofing and cladding applications. Known for their exceptional strength, lightweight properties, and UV resistance, these panels provide a perfect balance of durability and design flexibility.

Whether for residential, commercial, or industrial projects, polycarbonate roofing and cladding deliver long-lasting performance and aesthetic appeal. In the following sections, we’ll explore the key reasons why polycarbonate panels stand out as the ideal solution.

Polycarbonate Panels Benefits

Durability & Impact Resistance

Polycarbonate panels offer outstanding durability. These panels resist impacts from hail, debris, and accidental knocks. Builders often choose polycarbonate panels for areas that need extra protection because they do not crack or shatter easily.

Lightweight strength makes polycarbonate panels easy to handle during installation. Their flexibility allows them to bend without breaking, which helps in areas with shifting temperatures or minor structural movement.

Light Transmission & UV Protection

Polycarbonate panels allow natural light to pass through while blocking harmful ultraviolet rays. This feature creates bright indoor spaces without the risks of sun damage. Many greenhouses and skylights use polycarbonate panels for this reason.

A table below shows how polycarbonate panels compare to other materials in light transmission:

| Material | Light Transmission (%) | UV Protection |

|---|---|---|

| Polycarbonate | 80-90 | Yes |

| Glass | 85-90 | No |

| Metal Roofing | 0 | N/A |

Polycarbonate panels do not discolor easily. They keep their clarity and appearance for many years, even with constant sun exposure.

Heat & Weather Resistance

Polycarbonate panels withstand extreme temperatures, heavy rain, and snow. These panels do not warp or become brittle in hot or cold weather. Builders use polycarbonate panels in climates with harsh weather because they maintain their shape and strength.

Polycarbonate panels also resist corrosion and rust. This makes them a better choice than metal in humid or coastal areas.

Soundproofing & Insulation

Polycarbonate panels provide good sound insulation. They help reduce noise from rain, wind, or nearby traffic. Many schools and offices use polycarbonate panels to create quieter indoor spaces.

These panels also offer thermal insulation. Polycarbonate panels help keep buildings warm in winter and cool in summer, which can lower energy costs.

- Polycarbonate panels are cost-effective because they last long and require little maintenance.

- Their lightweight design makes installation faster and easier, saving time and labor costs.

Roofing Applications

Residential Uses

Homeowners often choose polycarbonate panels for their roofing projects. These panels reduce the overall weight on the structure, which helps prevent stress on walls and foundations. Many people use polycarbonate panels for patios, carports, and greenhouses.

Polycarbonate panels offer versatility in design. They come in clear, tinted, and textured options. This variety allows homeowners to select panels that match the style of their house.

Commercial & Industrial

Builders use polycarbonate panels in many commercial and industrial roofing applications. Warehouses, factories, and sports facilities benefit from the lightweight nature of these panels. The reduced structural load makes installation easier and lowers construction costs.

Polycarbonate panels provide strong protection against weather and impacts. They resist damage from hail, wind, and debris. Many businesses prefer these panels for their durability and long lifespan.

Aesthetic options also play a role in commercial settings. Companies can choose panels that enhance the appearance of their buildings. The flexibility in design supports both functional and visual goals.

- Polycarbonate panels support energy efficiency by allowing natural light into large spaces.

- These panels help create safer and more attractive environments for workers and visitors.

Polycarbonate vs Other Materials

Glass

Glass panels offer high clarity and a classic look. They break easily when hit by debris or during storms. Many builders choose polycarbonate panels because they resist impacts and weigh less than glass.

Glass requires strong support structures. This increases building costs and installation time. Polycarbonate panels need less support, which makes them easier to install.

Metal

Metal roofing panels last a long time and resist fire. They do not allow natural light into buildings. Polycarbonate panels let sunlight pass through, which helps brighten indoor spaces.

Metal panels can rust in humid or coastal areas. Polycarbonate panels resist corrosion and do not rust. Metal roofs often feel hot in summer and cold in winter, while polycarbonate panels help regulate indoor temperatures.

| Feature | Metal Panels | Polycarbonate Panels |

|---|---|---|

| Weight | Heavy | Lightweight |

| Light Passage | None | High |

| Rust Resistance | Low | High |

PVC

PVC panels cost less than other options. They do not last as long as polycarbonate panels. Builders notice that PVC panels crack and discolor over time.

PVC panels offer limited impact resistance. Polycarbonate panels stay strong and clear for many years. PVC does not provide the same level of insulation or soundproofing.

Practical Considerations

Lifespan & Maintenance

Polycarbonate roofing offers a long service life. Many builders choose this material because it resists damage from weather and impacts. Regular cleaning with mild soap helps maintain clarity and strength.

Most polycarbonate sheet products require little maintenance. They do not rust or corrode, even in humid climates. Owners can inspect panels once a year to check for dirt or debris.

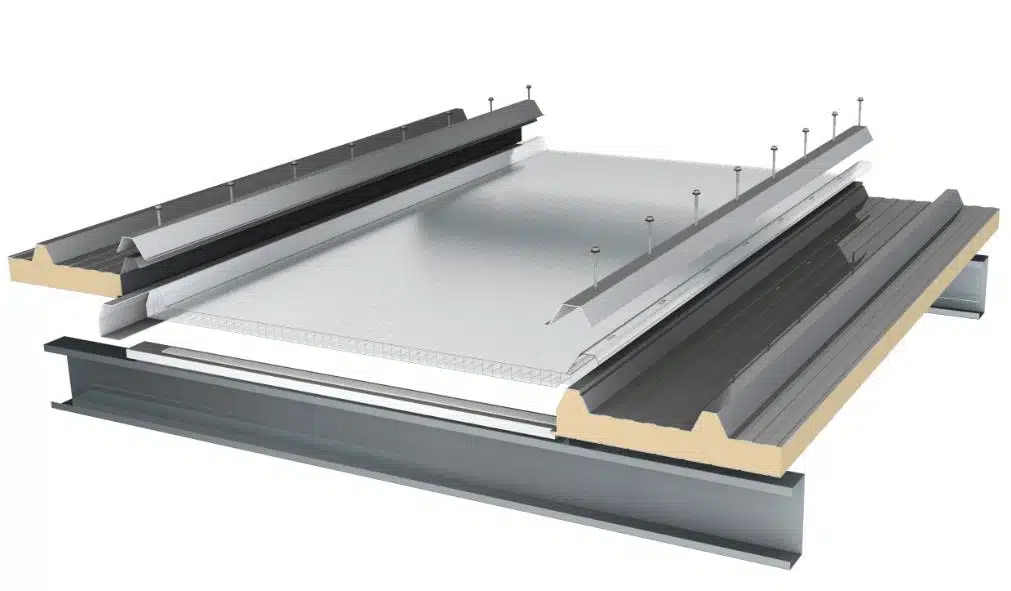

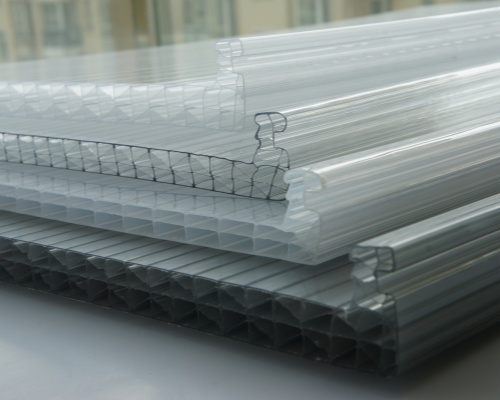

Polycarbonate Types

Polycarbonate roofing comes in several types. Solid polycarbonate sheet panels provide high impact resistance and clear visibility. Twin-wall polycarbonate sheet panels offer better insulation and reduce heat loss.

Multiwall polycarbonate sheet panels combine strength with lightweight design. Builders use these panels for greenhouses and skylights. Each type suits different needs and budgets.

| Type | Features | Common Uses |

|---|---|---|

| Solid Sheet | High clarity, strong | Skylights, canopies |

| Twin-Wall Sheet | Insulation, lightweight | Greenhouses |

| Multiwall Sheet | Extra insulation | Industrial roofing |

Design Flexibility

Polycarbonate roofing supports many design options. Panels come in clear, tinted, and textured finishes. Builders can shape polycarbonate sheet panels to fit curved or angled roofs.

Many architects use polycarbonate roofing for modern designs. The material adapts to different styles and structures. This flexibility helps create unique and attractive buildings.

- Polycarbonate roofing panels work for both small and large projects.

- Designers can mix colors and finishes for custom looks.

- The lightweight nature of polycarbonate roofing makes installation easier.

Sustainability and Eco-Friendly Benefits

Recyclability of polycarbonate

Polycarbonate roofing panels support sustainable building practices. Manufacturers can recycle these panels at the end of their lifespan. This process reduces waste in landfills and helps conserve resources.

Many builders choose polycarbonate roofing solutions because they want to lower their environmental impact. Recycled polycarbonate can become new panels or other useful products. This cycle supports a greener construction industry.

Energy Savings with Natural Lighting

Clear polycarbonate roofing allows sunlight to enter buildings. This feature reduces the need for artificial lighting during the day. Natural light creates a comfortable indoor environment and helps save electricity.

Energy-efficient buildings often use polycarbonate panels to improve lighting and lower energy bills. These panels help regulate indoor temperatures by blocking UV rays and providing insulation. Builders can design spaces that use less energy and offer better comfort.

- Polycarbonate panels support green building certifications.

- Natural lighting from these panels improves well-being for occupants.

- Lower energy use benefits both the environment and building owners.

Choosing the Right Polycarbonate Panels

Thickness options and their applications

Polycarbonate panels come in a range of thicknesses. Each thickness serves a different purpose in construction. Thinner panels, such as 4mm or 6mm, work well for greenhouses and small awnings.

Thicker panels, like 10mm or 16mm, provide better insulation and strength. Builders often use these for skylights, carports, or industrial roofing. The right thickness helps the panel resist impacts and weather changes.

The table below shows common thicknesses and their typical uses:

| Thickness (mm) | Common Applications |

|---|---|

| 4-6 | Greenhouses, sheds |

| 8-10 | Carports, patios |

| 16+ | Industrial roofs, skylights |

Key Factors to Consider

Selecting the best polycarbonate roofing panels depends on several factors. Location plays a key role. Areas with heavy snow or strong winds need thicker, stronger panels.

Climate affects the choice as well. Hot regions benefit from panels with UV protection and heat resistance. Cold climates require panels that can handle freezing temperatures without cracking.

Project type also matters. Residential projects may focus on appearance and light transmission. Industrial projects often need panels that provide maximum strength and insulation.

- Builders should check local building codes before choosing panel thickness.

- Consider the amount of sunlight and weather exposure at the site.

- Think about the long-term maintenance needs for each project.

Conclusion

Polycarbonate panels offer outstanding performance for roofing. Roofing projects benefit from their strength and impact resistance. Roofing with polycarbonate panels ensures long-lasting durability. Many roofing systems use these panels for their lightweight design. Roofing installations become easier and faster with polycarbonate. Roofing structures gain protection from harsh weather. Roofing with polycarbonate panels reduces maintenance needs. Roofing applications see improved energy efficiency. Roofing spaces stay brighter with natural light. Roofing in residential and commercial settings looks modern. Roofing costs decrease due to easy installation. Roofing panels made from polycarbonate resist discoloration. Roofing projects achieve long-term value and versatility.